Penetration Grade Bitumen: Its Uses, Applications, Advantages, Disadvantages, and Price Factors

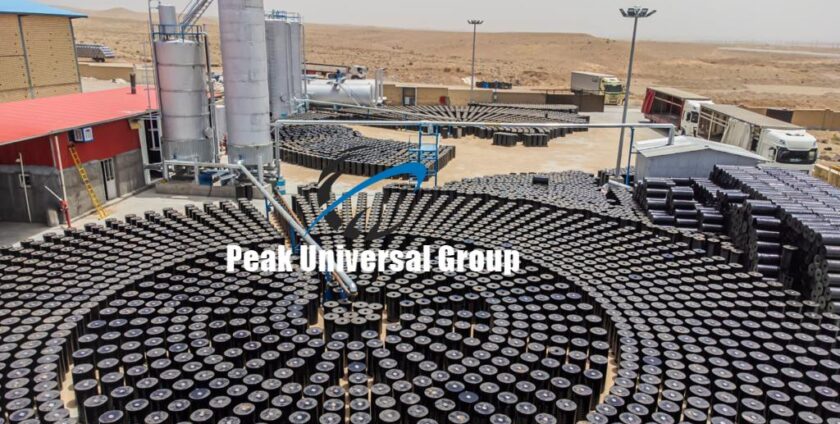

What is Penetration Grade Bitumen? Penetration grade bitumen, often simply referred to as penetration bitumen, is a crucial material in the construction and road building industries. This blog aims to provide an in-depth understanding of penetration grade bitumen, exploring its uses, applications, advantages, disadvantages, and price factors. With Peak Universal Business as your supplier, you can be assured of high-quality products that meet industry standards.

What is Penetration Grade Bitumen?

Definition

Penetration grade bitumen is a type of bitumen classified based on its hardness or penetration capacity. The penetration test, which measures the depth a standard needle penetrates the bitumen under specific conditions, determines its grade. The result, measured in tenths of a millimeter, indicates the bitumen’s softness or hardness. Common grades include 10/20, 30/40, 40/50, 40/60, 60/70, 80/100 and 100/150, where the numbers represent the penetration depth range.

Chemical Composition

Penetration bitumen is a complex mixture of hydrocarbons, predominantly asphaltenes, resins, and oils. Its composition includes:

- Asphaltenes: Provide hardness and contribute to the bitumen’s viscosity.

- Resins: Offer adhesiveness and flexibility.

- Oils: Impart fluidity and workability to the bitumen.

Physical Properties

- Color: Black or dark brown

- Consistency: Varies from semi-solid to solid

- Melting Point: Ranges from 35°C to 65°C, depending on the grade

- Solubility: Soluble in carbon disulfide and specific organic solvents

Grades of Penetration Bitumen

Penetration bitumen is classified based on its hardness or penetration value, which indicates the depth a standard needle penetrates the bitumen under specified conditions. Here are short descriptions for the various grades of penetration bitumen, including their typical applications:

1.Penetration Bitumen 10/20

Description: Bitumen 10/20 is one of the hardest grades of penetration bitumen. It has a very low penetration value, indicating high stiffness and hardness.

Applications: This grade is commonly used in very heavy traffic road construction, airfield pavements, and industrial applications where high resistance to deformation is required.

2.Penetration Bitumen 30/40

Description: Bitumen 30/40 is a hard grade with a low penetration value, making it stiff and durable.

Applications: It is used in the construction of high-stress pavements, such as highways, intersections, and other areas subjected to heavy traffic loads.

3.Penetration Bitumen 40/50

Description: Bitumen 40/50 has a moderate hardness, with a penetration value that balances stiffness and flexibility.

Applications: This grade is ideal for road base and binder courses in flexible pavements, providing a durable and resilient surface suitable for moderate to heavy traffic conditions.

4.Penetration Bitumen 40/60

Description: Bitumen 40/60 offers a slightly higher penetration value than 40/50, providing a bit more flexibility while maintaining good hardness.

Applications: It is typically used in similar applications as 40/50, including road base and binder courses, especially in regions with moderate temperature variations.

5.Penetration Bitumen 60/70

Description: Bitumen 60/70 is one of the most commonly used penetration grades, offering a good balance between hardness and flexibility.

Applications: It is widely used in the construction of asphalt pavements, roads, and highways, providing a durable surface for a variety of traffic conditions.

6.Penetration Bitumen 80/100

Description: Bitumen 80/100 has a higher penetration value, making it softer and more flexible compared to lower penetration grades.

Applications: This grade is suitable for use in regions with colder climates where a more flexible pavement is required to prevent cracking. It is also used in the production of asphalt mixtures for light to moderate traffic roads.

7.Penetration Bitumen 100/150

Description: Bitumen 100/150 is one of the softest grades, with a high penetration value indicating significant flexibility.

Applications: It is used in the construction of pavements and surfaces in very cold regions where maximum flexibility is necessary to accommodate thermal movements and prevent brittleness. Additionally, it is used in some industrial applications requiring a softer binder.

Each grade of penetration bitumen has specific properties that make it suitable for different environmental conditions and traffic loads. Selecting the appropriate grade ensures the longevity and performance of the constructed pavement or structure. With Peak Universal Business as your supplier, you can access a wide range of penetration bitumen grades tailored to your project’s requirements.

Manufacturing Process of Penetration Grade Bitumen:

1. Distillation

The manufacturing of penetration grade bitumen begins with the distillation of crude oil. Crude oil is heated in a distillation column, separating it into various fractions. The heaviest fractions, which do not vaporize, are collected at the bottom of the column. These fractions form the basis of bitumen.

2. Aeration and Oxidation

The heavy fractions undergo further processing to improve their properties. This involves aeration and oxidation, where air is blown through the bitumen at high temperatures. This process increases the asphaltene content, enhancing the bitumen’s viscosity and hardness.

3. Blending and Grading

The processed bitumen is then blended to achieve the desired penetration grade. By adjusting the proportions of different bitumen types, manufacturers can produce specific grades, such as 60/70 or 80/100.

4. Quality Control

The final product undergoes rigorous quality control tests to ensure it meets industry standards. Tests include penetration, softening point, ductility, and viscosity measurements.

Uses and Applications of Penetration Grade Bitumen

1. Road Construction

Paving and Surfacing

Penetration grade bitumen is extensively used in road construction for paving and surfacing. It binds aggregate particles, forming a durable and weather-resistant road surface.

Road Repair and Maintenance

It is also used in road repair and maintenance, including patching potholes and resurfacing worn-out roads.

2. Roofing

Penetration bitumen is a key material in roofing applications. It is used in the production of roofing felt and shingles, providing waterproofing and protection against weather elements.

3. Waterproofing

Building Foundations

Penetration grade bitumen is applied to building foundations to prevent water ingress and protect structural integrity.

Underground Structures

It is used in waterproofing underground structures, such as basements and tunnels, to prevent water seepage and damage.

4. Industrial Applications

Pipe Coating

Penetration bitumen is used to coat pipes, protecting them from corrosion and extending their lifespan.

Asphalt Production

It is a crucial component in the production of asphalt for various industrial applications, including manufacturing asphalt concrete and bituminous mixtures.

5. Other Applications

Adhesives and Sealants

Penetration bitumen is used in the production of adhesives and sealants, providing strong bonding, and sealing properties.

Damp-proof Courses

It is applied in damp-proof courses to prevent rising damp in walls and structures.

Advantages of Penetration Grade Bitumen

1. Durability

Penetration bitumen provides long-lasting durability, making it ideal for road construction and other applications where longevity is crucial.

2. Versatility

Its versatile nature allows it to be used in various applications, from road construction to waterproofing and industrial uses.

3. Waterproofing Properties

Penetration bitumen offers excellent waterproofing properties, protecting structures from water damage and enhancing their lifespan.

4. Adhesive Properties

It has strong adhesive properties, making it effective in binding aggregates and other materials in construction and industrial applications.

5. Cost-Effective

Penetration bitumen is a cost-effective material, providing excellent performance at a relatively low cost compared to other materials.

6. Thermal Stability

It has good thermal stability, maintaining its properties over a wide range of temperatures, which is crucial for applications in varying climates.

Disadvantages of Penetration Grade Bitumen

1. Temperature Sensitivity

Penetration bitumen can become brittle at low temperatures and soft at high temperatures, affecting its performance in extreme climates.

2. Environmental Impact

The production and use of bitumen have environmental impacts, including greenhouse gas emissions and potential pollution during manufacturing and application.

3. Health and Safety Concerns

Handling and applying bitumen require safety precautions to prevent exposure to fumes and contact with skin, as it can cause irritation and health issues.

4. Aging and Degradation

Over time, bitumen can age and degrade, losing its effectiveness and requiring maintenance or replacement.

5. Limited Flexibility

Compared to polymer-modified bitumen, penetration grade bitumen has limited flexibility, which can lead to cracking under heavy loads or temperature fluctuations.

Price Factors of Penetration Grade Bitumen

1. Crude Oil Prices

The price of penetration grade bitumen is closely linked to crude oil prices. Fluctuations in the global oil market directly impact bitumen prices.

2. Production Costs

The costs associated with refining, processing, and blending bitumen influence its price. Advanced processes and quality control measures can increase production costs.

3. Supply and Demand

Market demand for bitumen in construction, industrial, and infrastructure projects affects its price. High demand can drive prices up, while low demand can lead to price reductions.

4. Transportation and Logistics

The cost of transporting bitumen from production facilities to end-users plays a role in its pricing. Factors such as distance, transportation mode, and fuel costs influence these expenses.

5. Regulatory Factors

Regulations and environmental policies affecting bitumen production and use can impact its price. Compliance with safety and environmental standards can increase costs.

6. Quality and Grade

The specific grade and quality of penetration bitumen also affect its price. Higher grades with better performance characteristics typically command higher prices.

Peak Universal Business: Your Trusted Supplier of Penetration Grade Bitumen

Peak Universal Business is a leading supplier of high-quality penetration grade bitumen, catering to the diverse needs of the construction and industrial sectors. Here’s why Peak Universal Business stands out:

- Quality Assurance

Peak Universal Business ensures that all their bitumen products meet the highest quality standards, providing reliable and consistent performance.

- Wide Range of Products

They offer a wide range of penetration grade bitumen products, including various grades to suit different applications and requirements.

- Customized Solutions

Peak Universal Business provides customized solutions tailored to the specific needs of their clients, ensuring optimal performance and satisfaction.

- Technical Expertise

With a team of experienced professionals, Peak Universal Business offers technical support and guidance to help clients choose the right bitumen products for their projects.

- Sustainable Practices

Committed to sustainability, Peak Universal Business ensures that their products are produced and supplied in an environmentally responsible manner.

- Competitive Pricing

Peak Universal Business offers competitive pricing without compromising on quality, making them a cost-effective choice for customers.

Conclusion

Penetration grade bitumen is a versatile and essential material in the construction and industrial sectors. Understanding its manufacturing process, uses, applications, advantages, disadvantages, and price factors is crucial for making informed decisions. With Peak Universal Business as your trusted supplier, you can be assured of high-quality penetration bitumen products that meet industry standards and deliver exceptional performance.

Whether you are involved in road construction, roofing, waterproofing, or industrial applications, penetration grade bitumen offers the durability, versatility, and cost-effectiveness you need. Choose Peak Universal Business for all your bitumen needs and experience the benefits of working with a reliable and experienced supplier.

You can Read More about Penetration Bitumen Here:

How is Penetration Bitumen produced ?

Penetration Bitumen 80/100 Uses & Its Advantages

Industrial uses of Penetration Bitumen 60/70

What is the penetration bitumen 60/70 & its uses?

Uses of penetration bitumen 40/60

If You have any other Query or Question you want to ask, Please don’t hesitate to Contact Us

- 0 comment

Leave a Reply