Penetration Test of Bitumen: Details of Process & Purpose

The penetration test of bitumen is a fundamental procedure in bituminous material testing. It plays a vital role in classifying bitumen grades based on hardness and consistency. This test is especially crucial for ensuring that the chosen bitumen performs effectively under varying traffic loads and climate conditions.

In this post, you’ll discover the purpose, process, equipment, and interpretation of penetration testing along with its importance in road construction and industrial applications and why Peak Universal Business is your trusted supplier for high-quality penetration bitumen.

❓ What is the Penetration Test of Bitumen?

The penetration test measures the hardness or softness of bitumen by determining the depth a standard needle penetrates under specific conditions. The result, expressed in tenths of a millimeter (dmm), is used to classify bitumen into different grades (e.g., 60/70, 80/100).

✅ Purpose of the Test:

-

Assess the consistency of bitumen.

-

Ensure suitability for the local temperature and traffic conditions.

-

Help in selecting the appropriate grade for construction applications.

Purpose of the Penetration Test

The primary purpose of the penetration test of bitumen is to determine its hardness or consistency. This information is crucial for:

- Quality Control: Ensuring that the bitumen meets the specified standards for a particular project.

- Performance Prediction: Predicting how the bitumen will behave under different traffic loads and climatic conditions.

- Material Selection: Choosing the appropriate grade of bitumen for specific applications.

- Specification Compliance: Verifying that the bitumen complies with the relevant specifications and standards.

🏭 Penetration Test Procedure: Step-by-Step

The penetration test is a standardized procedure that involves several steps. Here is a detailed breakdown of the process: Sample Preparation, Conditioning, Penetration Measurement, Recording Results

1. 🧊 Sample Preparation

- Heating: The bitumen sample is heated to a fluid state to ensure it is homogeneous and free of air bubbles and moisture. (Sample Preparation)

- Pouring: The heated bitumen is then poured into a standard container, typically a metal or glass cup, and allowed to cool to room temperature. (Sample Preparation)

The bitumen sample is poured into a container and cooled to room temperature. It must be air-free and level.

2. 🌡️ Conditioning

- Temperature Control: The sample is placed in a water bath maintained at a temperature of 25°C (77°F) for at least one hour before testing.

- Standard Conditions: The test conditions, including temperature, loading, and duration, are standardized to ensure consistent and accurate results.

The sample is placed in a water bath at 25°C for at least 60–90 minutes to stabilize temperature before testing.

3. 🧪 Setup of Penetrometer

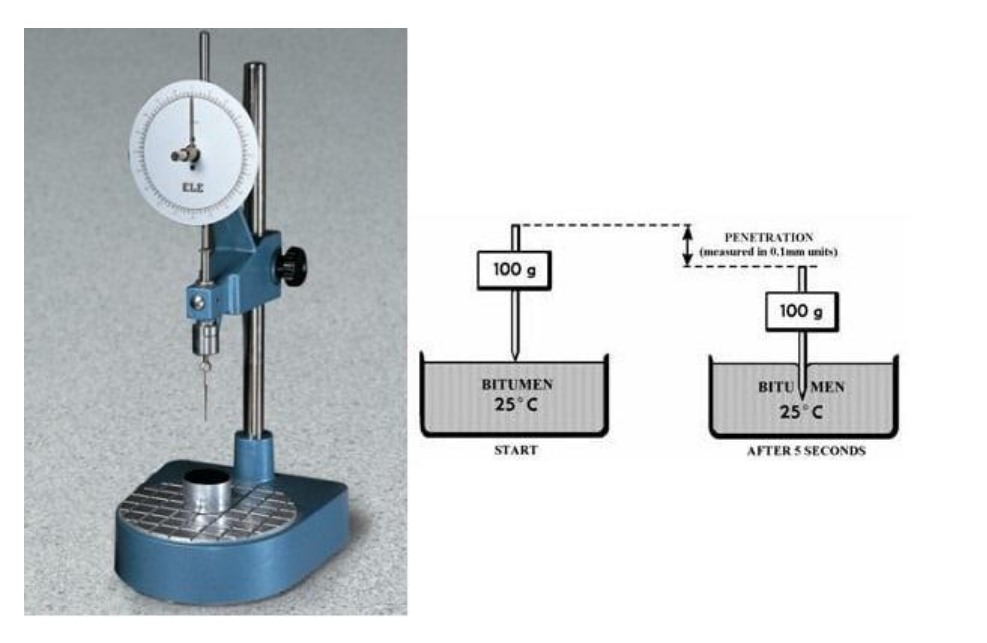

A penetrometer device with a standard needle (100g load) is used. The needle is lowered gently until it just touches the bitumen surface.

4. ⏱️ Penetration Testing

- Penetration Apparatus: The testing apparatus consists of a standard needle (weighing 100 grams) mounted on a movable arm. (Penetration Measurement)

- Positioning: The needle is positioned to just touch the surface of the bitumen sample.

- Loading: The needle is released and allowed to penetrate the bitumen for a specified duration, usually 5 seconds.

- Measurement: The depth of penetration is measured in tenths of a millimetre using a dial gauge or digital readout.

The needle is allowed to penetrate the bitumen vertically for 5 seconds. The depth of penetration is recorded in dmm.

5. 🔁 Repetition & Average

- Multiple Tests: Typically, three penetration tests are conducted on the same sample to ensure accuracy and repeatability. (Recording Results)

- Average Value: The average penetration value is calculated and recorded as the penetration grade of the bitumen. (Recording Results)

The process is repeated at least 3 times at different points on the sample, and the average is taken as the final result.

Factors Affecting the Penetration Test

Several factors can influence the results of the penetration test, including:

- Temperature: The temperature of the bitumen sample and the testing environment significantly impacts the penetration value. Higher temperatures result in higher penetration values (softer bitumen), while lower temperatures result in lower penetration values (harder bitumen).

- Needle and Load: The standard needle and weight (100 grams) must be used to ensure consistency. Any deviation from these standards can affect the test results.

- Duration: The duration for which the needle is allowed to penetrate the bitumen is standardized at 5 seconds. Any variation in this time can lead to inconsistent results.

- Sample Homogeneity: The bitumen sample must be homogeneous and free from air bubbles and moisture. Any impurities or inconsistencies in the sample can affect the penetration value.

📊 Interpretation of Results

| Bitumen Grade | Penetration Range (dmm) | Description |

|---|---|---|

| 35/50 | 35 – 50 | Very Hard Bitumen |

| 60/70 | 60 – 70 | Medium Hardness Bitumen |

| 80/100 | 80 – 100 | Soft Bitumen |

| 100/120 | 100 – 120 | Very Soft Bitumen |

-

Lower penetration value = harder bitumen (suitable for hot climates).

-

Higher penetration value = softer bitumen (suitable for cold climates).

Significance of Penetration Test Results

The results of the penetration test provide valuable information about the bitumen’s performance characteristics:

- Hardness and Softness: The penetration value indicates the hardness or softness of the bitumen. Lower penetration values denote harder bitumen, while higher values indicate softer bitumen.

- Viscosity and Temperature Sensitivity: The penetration test helps in understanding the viscosity of the bitumen and its sensitivity to temperature changes. This is crucial for determining the suitability of bitumen for different climatic conditions.

- Grade Classification: Based on the penetration value, bitumen is classified into various grades, such as 30/40, 60/70, and 80/100. Each grade has specific applications and performance characteristics.

- Quality Assurance: The penetration test ensures that the bitumen meets the required quality standards and specifications, providing confidence in its performance for construction projects.

🏗️ Industrial Applications Based on Penetration Grade

Penetration bitumen is used in a wide range of applications in the construction industry. Some of the key applications include:

🛣️ Road Construction

Each bitumen grade is chosen according to traffic load and environmental conditions. For example:

-

35/50 for airport runways and industrial roads.

-

60/70 for highways in temperate zones.

-

80/100 for urban streets and colder climates.

🏢 Foundation Waterproofing

Harder grades like 35/50 are preferred for barrier coatings in building foundations and tunnels.

🧱 Roofing & Coating

Softer bitumen with high penetration values are used in roofing membranes due to better flexibility.

🌍 Global Trade & Standards

The penetration value helps bitumen exporters meet international standards (ASTM D5, EN 1426) for various regions.

✅ Advantages of Penetration Testing

-

🔍 Accurate Material Classification: Helps choose the right grade.

-

📏 Standardized Test: Globally recognized method.

-

⚙️ Quality Control: Ensures batch consistency in production.

-

🛠️ Infrastructure Durability: Informs design decisions for better road life.

Penetration bitumen offers several advantages that make it a preferred choice for construction projects:

- Versatility: It is suitable for a wide range of applications, from road construction to industrial flooring, due to its variable hardness and consistency.

- Durability: Penetration bitumen provides a durable and resilient surface that can withstand heavy traffic loads and adverse weather conditions.

- Temperature Sensitivity: The penetration test provides valuable information about the temperature sensitivity of bitumen, helping in the selection of appropriate grades for different climatic conditions.

- Cost-Effective: Penetration bitumen is cost-effective, offering a balance between performance and cost, making it a popular choice for infrastructure projects.

- Quality Assurance: The penetration test ensures that the bitumen meets the required quality standards and specifications, providing confidence in its performance for construction projects.

Disadvantages of Penetration Bitumen

While penetration bitumen offers numerous advantages, it also has some limitations:

- Temperature Sensitivity: Bitumen’s performance can be significantly affected by temperature changes, leading to issues like rutting in high temperatures and cracking in low temperatures.

- Oxidation: Over time, bitumen can oxidize and harden, reducing its flexibility and making it more prone to cracking.

- Environmental Impact: The production and use of bitumen have environmental implications, including the release of greenhouse gases and potential contamination of soil and water.

Penetration Test vs. Other Bitumen Tests

| Property/Test | Penetration Test | Softening Point | Viscosity Test |

|---|---|---|---|

| Measures | Hardness | Temperature Softening | Flow Resistance |

| Unit | dmm | °C | Poise or Seconds |

| Best for | Grading Bitumen | Heat Resistance | Pavement Design |

Quality Control and Testing

Quality control is essential to ensure the Performance and Durability of penetration bitumen. In addition to the penetration test, several other tests are conducted to assess the quality of bitumen:

- Softening Point Test: Determines the temperature at which bitumen softens and flows, providing information about its temperature susceptibility.

- Ductility Test: Measures the ability of bitumen to deform under tensile stress, indicating its flexibility and resistance to cracking.

- Viscosity Test: Assesses the flow properties of bitumen, providing information about its workability and performance at different temperatures.

- Flash Point Test: Determines the temperature at which bitumen emits vapors that can ignite, indicating its safety during handling and application.

- Specific Gravity Test: Measures the density of bitumen, providing information about its composition and quality.

Peak Universal Business: Your Trusted Supplier in Dubai

When sourcing penetration bitumen in Dubai, Peak Universal Business stands out as a reliable and reputable supplier. Here’s why:

- High-Quality Standards: We adhere to stringent quality control measures to ensure our products meet the highest standards of purity and effectiveness.

- Diverse Product Range: Our range includes various grades and packaging options to suit different needs, from small quantities for personal use to bulk orders for industrial applications.

- Expertise and Experience: With years of experience in the industry, we understand the unique requirements of our clients and provide tailored solutions.

- Competitive Pricing: We offer competitive prices without compromising on quality, making us a cost-effective choice for businesses and consumers alike.

- Customer Service: Our dedicated customer support team is always ready to assist with any queries or special requests, ensuring a seamless purchasing experience.

❓ FAQ about Penetration Test of Bitumen Process

❓ What does the penetration value mean in bitumen?

📏 The penetration value (in dmm) shows how soft or hard the bitumen is. A lower value means harder bitumen; a higher value indicates softer consistency.

❓ Why is the test performed at 25°C?

🌡️ 25°C is the standard reference temperature because it mimics average road conditions. This ensures consistent comparisons across samples.

❓ Can the penetration value affect road performance?

🛣️ Yes, using the wrong grade can cause pavement failure. For example, soft bitumen in hot climates may lead to rutting or bleeding.

❓ Is the penetration test applicable for modified bitumen?

⚗️ Not entirely. Polymer-modified or oxidized bitumen requires additional testing like viscosity or softening point.

❓ How is penetration grade bitumen labeled internationally?

🌍 It’s typically labeled by range (e.g., 60/70), indicating penetration depth. It aligns with standards like ASTM D5 and EN 1426.

📌 Conclusion- Penetration Test of Bitumen

The penetration test of bitumen is more than a lab procedure—it’s a gateway to ensuring durability and safety in construction. By evaluating hardness, engineers can select the right material for specific climates and loads. Whether for airport runways, highways, or waterproofing systems, understanding penetration values ensures better infrastructure and optimized performance.

As a trusted supplier in Dubai, Peak Universal Business is committed to providing high-quality penetration bitumen to meet the diverse needs of our clients. Whether you require small quantities for personal use or bulk orders for industrial applications, we have the expertise and resources to fulfill your requirements efficiently and reliably.

The Process of the Penetration Test Details: Sample Preparation, Conditioning, Penetration Measurement, Recording Results,

📣Call to Peak Universal Business

👉 Need lab-grade bitumen or technical advice?

📌 Get in touch for:

-

🧪 Certified bitumen with test reports

-

📦 Bulk and drum packaging options

-

📊 Engineering consultation for material selection

🔹 Request a Quote | 🔹 Download TDS | 🔹 Talk to a Bitumen Specialist

📧 Email: [email protected]

📞 Phone: +971 4 878 2031

🌐 Visit: PUBLtd. VG Bitumens

If You have any other Query or Question you want to ask, Please don’t hesitate to Contact Us.

- 0 comment

Leave a Reply