What is Paraffin? Its Uses, Applications, and Benefits

Paraffin is one of those materials most people use every day often without realizing it. From lighting a candle to applying skincare, from food packaging to industrial insulation, paraffin quietly supports countless products and processes around the world.

Yet despite its widespread presence, paraffin remains misunderstood. Many people ask: What exactly is paraffin? Where does it come from? Is it safe? And why do so many industries rely on it?

This comprehensive guide answers all those questions. It blends easy-to-understand explanations with technical and engineering insights, giving you a complete view of paraffin, its types, properties, manufacturing process, applications, and benefits. We will also highlight Peak Universal Business as a reliable supplier of paraffin.

1. What Is Paraffin?

Paraffin refers to a group of saturated hydrocarbons (alkanes) derived primarily from petroleum refining. Chemically, these hydrocarbons follow the formula CnH₂n+₂, which gives paraffin its stable, non-reactive nature.

In practical terms, paraffin is:

-

Colorless or white

-

Odorless and tasteless

-

Hydrophobic (repels water)

-

Chemically inert and stable

Because of these properties, its works exceptionally well in applications that require purity, consistency, safety, and durability.

Common Forms of Paraffin

Paraffin exists in three main physical forms:

-

Paraffin Wax – solid

-

Liquid Paraffin (Mineral Oil) – liquid

-

Soft Paraffin (Petroleum Jelly) – semi-solid

Each form serves different industries, yet all share the same hydrocarbon foundation.

2. Types of Paraffin

Understanding the different types of paraffin is essential because each has unique properties and applications.

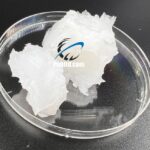

2.1 Paraffin Wax

Wax is the solid form a white, odorless wax with a melting point between 46°C and 68°C (115°F – 154°F). The exact melting point depends on the oil content and refining level.

Key Technical Properties:

-

High purity when fully refined

-

Low oil content

-

Clean-burning behavior

-

Excellent fragrance and dye retention

-

Good electrical insulation properties

Typical Uses:

-

Candle manufacturing

-

Cosmetic formulations

-

Food-grade coatings

-

Rubber and tire processing

-

Electrical insulation

Paraffin wax remains the global standard for large-scale candle production due to its consistency, cost efficiency, and performance.

2.2 Liquid Paraffin (Mineral Oil)

Liquid Wax is a clear, colorless oily liquid. It is made through highly refined hydrocarbon extraction from petroleum.

Technical Characteristics:

-

Non-toxic (pharmaceutical grade)

-

High oxidative stability

-

Low volatility

-

Excellent lubrication properties

Applications Include:

-

Cosmetics and skincare

-

Baby oils and lotions

-

Pharmaceutical laxatives

-

Industrial lubrication

-

Textile and machinery oils

From an engineering perspective, liquid paraffin is valued for its chemical neutrality, making it compatible with sensitive formulations.

2.3 Soft Paraffin (Petroleum Jelly)

Soft Wax is a semi-solid blend of hydrocarbons that forms an occlusive protective barrier.

Key Benefits:

-

Prevents moisture loss

-

Chemically inert

-

Dermatologically safe

Common Uses:

-

Medical ointments

-

Skin protectants

-

Pharmaceutical bases

-

Lip and wound care products

It is one of the most trusted materials in dermatology and healthcare worldwide.

3. Physical and Chemical Properties of Paraffin

| Property | Typical Range |

|---|---|

| Color | White / Colorless |

| Odor | Odorless |

| Melting Point (Wax) | 46–68°C |

| Boiling Point | ~370°C |

| Density | 0.88–0.94 g/cm³ |

| Solubility | Insoluble in water |

| Chemical Reactivity | Very low |

These properties explain why paraffin performs reliably in thermal, mechanical, and chemical environments.

- Color: White or colorless

- Odor: Odorless

- Melting Point: 46-68°C (115-154°F) for paraffin wax

- Boiling Point: Approximately 370°C (698°F) for liquid paraffin

- Solubility: Insoluble in water, soluble in organic solvents like ether, benzene, and certain oils

- Density: 0.88-0.94 g/cm³ for paraffin wax, 0.8-0.9 g/cm³ for liquid paraffin

4. How Paraffin Is Manufactured (Technical Overview)

Paraffin is produced during petroleum refining, following a multi-stage purification process.

Step 1: Fractional Distillation

Crude oil is heated and separated by boiling point. Paraffinic fractions appear in heavier distillates.

Step 2: Dewaxing

The oil fraction is cooled so wax crystals form and can be separated using solvent filtration.

Step 3: Hydrofinishing & Hydrotreating

Hydrogen processing removes impurities, sulfur compounds, and unstable hydrocarbons.

Step 4: Bleaching and Blending

Final steps improve color, stability, and performance for specific applications.

Higher refinement levels make paraffin suitable for:

-

Food contact

-

Cosmetics

-

Pharmaceuticals

Higher refinement = safer usage in cosmetics, pharmaceuticals, and food applications.

Production and Refining:

Extraction Process

Paraffin is primarily extracted from crude oil during the refining process. The extraction involves several steps to isolate and purify the paraffin:

Distillation: Crude oil is heated in a distillation column to separate its components based on their boiling points. Paraffin is found in the middle distillates, which are collected and further processed.

De-waxing: The middle distillates are subjected to a de-waxing process to separate the paraffin wax from other hydrocarbons. This involves cooling the distillates to precipitate the wax, which is then filtered out.

Hydrofinishing: The paraffin wax is further purified through hydrofinishing, a process that uses hydrogen to remove impurities and improve the wax’s color and stability.

Processing and Refining

Once extracted, paraffin undergoes additional refining processes to enhance its properties and make it suitable for specific applications:

Bleaching: The wax is bleached to remove any remaining color impurities, resulting in a white or colorless product.

Hydrotreating: This process further purifies the paraffin by removing any remaining unsaturated hydrocarbons and other impurities.

Blending: Different grades of paraffin wax can be blended to achieve specific properties required for various applications.

Peak Universal Business ensures that their paraffin products undergo rigorous quality control during the refining process to deliver high-quality materials to their customers.

5. Major Uses and Applications of Paraffin

Paraffin is used in dozens of industries. Below is a comprehensive overview.

5.1 Paraffin in the Candle Industry

One of the most well-known uses of Wax is in the production of candles. Paraffin wax is an ideal material for candles due to its ability to burn cleanly and evenly, providing a steady flame and minimal smoke.

Paraffin wax is the world’s most common candle-making material. It offers:

-

A clean, stable burn

-

Excellent scent throw (cold and hot)

-

Smooth finish

-

Ability to mix with dyes and fragrances

Benefits in Candle Production

- Clean Burning: Paraffin wax produces a clean, steady flame with minimal soot.

- Versatility: It can be easily colored and scented, allowing for a wide range of candle designs.

- Cost-Effective: It is relatively inexpensive compared to other waxes, making it a popular choice for mass-produced candles.

- Stable: It has a stable melting point, ensuring consistent performance in various environmental conditions.

Compared to soy wax or beeswax, paraffin is more cost-effective and customizable, making it the first choice for mass candle production.

5.2 Industrial Applications

5.2.1 Packaging Industry

Paraffin is used as a protective coating for:

-

Cheese

-

Fruit

-

Paper packaging

-

Cardboard boxes

It acts as a moisture barrier, preserves freshness, and prevents contamination.

5.2.2 Rubber & Tire Manufacturing

Paraffin is blended into rubber to improve elasticity and protect against cracking caused by ozone exposure.

5.2.3 Lubrication

Liquid paraffin works well as:

-

Cutting oil

-

Anti-rust lubricant

-

Machine lubricating oil

-

Textile lubricant

Its clean and stable properties make it ideal where other oils may oxidize.

5.2.4 Electrical Insulation

Wax is an excellent electrical insulator. It is used in:

-

Transformers

-

Switches

-

Cable insulation

-

Electronic components

Its non-conductive nature makes it a reliable material in electrical engineering.

5.3 Medical and Therapeutic Applications

5.3.1 Paraffin Wax Therapy

A popular treatment in physiotherapy clinics and spas:

-

Hands, feet, elbows, and joints are dipped into warm paraffin wax

-

Heat penetrates tissues

-

Muscles relax

-

Blood flow increases

Benefits of therapy:

-

Reduced stiffness

-

Pain relief

-

Better joint mobility

-

Improved circulation

-

Moisturized skin

Suitable for arthritis, osteoarthritis, and chronic muscle pain.

5.3.2 Dermatology & Skincare

Soft paraffin and liquid paraffin are widely used to treat:

-

Dry skin

-

Eczema

-

Psoriasis

-

Dermatitis

-

Chapped lips

-

Cracked heels

They create a protective layer that prevents moisture loss.

5.3.3 Pharmaceuticals

Liquid paraffin is used as:

-

A mild laxative

-

A base for ointments

-

A carrier oil for medicines

Its safety in medicinal-grade form makes it a valuable pharmaceutical ingredient.

5.4 Cosmetic Applications

Paraffin is found in many beauty and hygiene products:

-

Lip balms

-

Face creams

-

Body lotions

-

Foundations

-

Mascara

-

Hair serums and pomades

-

Nail and cuticle treatments

It provides shine, smoothness, and stability to cosmetic formulations.

5.5 Household Uses

In homes, it is used for:

-

Waterproofing fabrics

-

Shoe polish

-

Furniture polish

-

Fire starters

-

Homemade candles

-

Preservation of metals

Its multi-purpose nature makes it a staple in DIY and household products.

Uses and Applications:

Paraffin’s unique properties make it suitable for a wide range of applications across various industries. Below are some of the most common uses and applications of paraffin:

Cosmetics and Personal Care Products

Paraffin wax and liquid paraffin (mineral oil) are commonly used in cosmetics and personal care products due to their emollient properties. They help to moisturize and protect the skin, making them valuable ingredients in a variety of products.

Applications in Cosmetics and Personal Care

Moisturizers and Lotions: Paraffin helps to lock in moisture, keeping the skin hydrated and smooth.

Lip Balms: It provides a protective barrier on the lips, preventing dryness and chapping.

Hair Care Products: Paraffin is used in hair conditioners and treatments to add shine and manageability to hair.

Creams and Ointments: Paraffin’s emollient properties make it a key ingredient in therapeutic creams and ointments for dry or irritated skin.

Food Industry

It is used in the food industry for various applications, particularly in food preservation and packaging.

Applications in the Food Industry

Coatings for Fruits and Vegetables: Wax is used to coat fruits and vegetables to preserve freshness and extend shelf life.

Cheese Coatings: It is applied to cheese to prevent moisture loss and protect against mold growth.

Confectionery: Paraffin wax is used to give a shiny appearance to chocolates and candies, as well as to prevent them from sticking together.

Packaging: It is used in food packaging materials to provide a moisture barrier and enhance durability.

Pharmaceuticals

Liquid paraffin, also known as mineral oil, is widely used in the pharmaceutical industry due to its medicinal properties. It is commonly used as a laxative and in topical medications.

Applications in Pharmaceuticals

Laxatives: mineral oil is used as an oral laxative to relieve constipation by lubricating the bowel and facilitating the passage of stool.

Topical Medications: It is used in ointments and creams to treat dry skin conditions and protect minor cuts and abrasions.

Carrier Oil: mineral oil is used as a carrier oil for active pharmaceutical ingredients in various formulations.

Industrial Applications

Paraffin finds numerous applications in various industrial processes and products due to its chemical stability and insulating properties.

Applications in Industry

Lubricants: It is used as a base oil in industrial lubricants to reduce friction and wear in machinery.

Insulation: It is used in electrical insulation materials due to its excellent dielectric properties.

Polishes: It is used in furniture and floor polishes to provide a protective, glossy finish.

Textiles: It is used in the textile industry for fabric finishing and waterproofing treatments.

Agriculture

Its used in agriculture for various purposes, including plant protection and preservation.

Applications in Agriculture

Plant Grafting: It is used to seal grafts and cuts in plants, promoting healing and preventing infection.

Fruit Preservation: It is used to coat fruits and vegetables to extend their shelf life and maintain their freshness during transportation and storage.

Seed Coatings: It is used to coat seeds to protect them from moisture and pests during storage and planting.

Arts and Crafts

It is a popular material in arts and crafts due to its versatility and ease of use. It is used in a variety of creative projects, from candle making to batik fabric dyeing.

Applications in Arts and Crafts

Candle Making: It is a staple material for creating a wide range of candles, from simple votives to elaborate sculpted designs.

Batik: It is used in the traditional art of batik fabric dyeing to create intricate patterns and designs.

Sculpting: It is used in sculpting and modeling to create detailed and durable artworks.

Wax Seals: It is used to create decorative wax seals for letters, invitations, and packaging.

Benefits of Using:

Paraffin offers numerous benefits across various industries due to its unique properties and versatility. Here are some of the key benefits of using paraffin:

1. Versatility

It is a highly versatile material that can be used in a wide range of applications. Its ability to adapt to different needs makes it an invaluable resource for manufacturers in various industries.

2. Cost-Effectiveness

It is relatively inexpensive compared to other materials with similar properties. This makes it a cost-effective choice for mass production and large-scale industrial applications.

3. Stability

It is chemically stable and resistant to environmental factors such as moisture, heat, and chemicals. This stability ensures consistent performance and long-lasting results in various applications.

4. Non-Toxic

It is non-toxic and safe for use in food, pharmaceuticals, and personal care products. Its inert nature makes it suitable for applications that require high levels of purity and safety.

5. Easy Processing

It is easy to process and mold, making it an ideal material for manufacturing. It can be easily melted, blended, and shaped to meet specific requirements.

6. Enhanced Product Performance

Paraffin enhances the performance of products in which it is used. Whether it is improving the burn quality of candles, providing moisture protection in cosmetics, or offering electrical insulation, paraffin contributes to better product performance and durability.

Paraffin Wax vs. Soy Wax

| Feature | Paraffin Wax | Soy Wax |

|---|---|---|

| Cost | Cheaper | More expensive |

| Scent Throw | Stronger | Mild |

| Burn Time | Faster | Longer |

| Eco-Friendliness | Lower | Higher |

Paraffin Wax vs. Beeswax

| Feature | Paraffin | Beeswax |

|---|---|---|

| Price | Affordable | Very expensive |

| Smoke | Minimal if refined | Very clean |

| Aroma | Neutral | Natural honey scent |

Each wax serves different needs depending on preference and industry.

Peak Universal Business: Your Reliable Supplier

- Commitment to Quality

Peak Universal Business is dedicated to providing high-quality paraffin that meets industry standards. Their rigorous quality control processes ensure that customers receive a product that performs reliably in various applications.

- Technical Expertise

With extensive experience in the paraffin industry, Peak Universal Business offers technical expertise to help customers optimize the use of paraffin in their products and processes. Their knowledgeable team is available to provide guidance and support.

- Reliable Supply Chains

Peak Universal Business maintains robust supply chains to ensure a consistent and timely supply of paraffin. Their strategic partnerships and efficient logistics operations guarantee that customers receive their orders on time.

- Customized Solutions

Recognizing that different industries and applications have unique requirements, Peak Universal Business offers customized solutions tailored to meet specific customer needs. They work closely with customers to understand their requirements and deliver paraffin products that align with their specifications.

- Focus on Sustainability

Peak Universal Business is committed to sustainability and environmental responsibility. They prioritize environmentally friendly practices in their operations and promote the use of Paraffin Wax as a sustainable material in various applications.

Conclusion

Paraffin is a versatile and valuable material with a wide range of uses and applications across various industries. Its unique properties make it suitable for everything from candle making and cosmetics to industrial processes and food preservation.

Peak Universal Business stands out as a reliable supplier of high-quality products, offering technical expertise, customized solutions, and a commitment to sustainability.

By understanding the properties, production process, and diverse applications of paraffin, manufacturers can make informed decisions to enhance their products and processes, ultimately achieving greater success in their industries.

Contact Details

📞 Phone: +971 4 878 2031

📧 Email: [email protected]

📦 P.O. Box: 417261

If You have any other Query or Question you want to ask, Please don’t hesitate to Contact Us.

- 0 comment

Leave a Reply