What is Rubber Process Oil? (RPO) is a specialized type of petroleum-derived oil that is primarily used in the rubber industry to improve the processing and performance of rubber compounds. It is a versatile and essential ingredient in the manufacturing of various rubber products, including tires, hoses, belts, seals, and gaskets. In this comprehensive product description, we will delve into the key characteristics, types, uses, and benefits of Rubber Process Oil (RPO), and why Peak Universal Business is your trusted supplier for high-quality RPO.

What is Rubber Process Oil (RPO)?

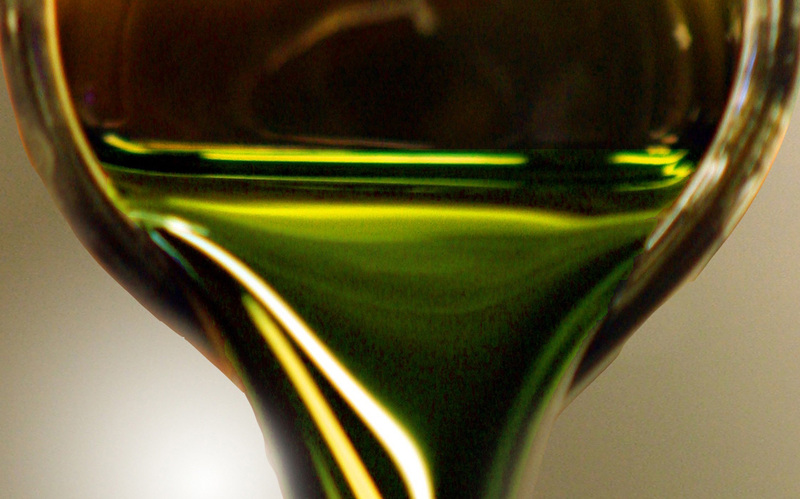

Rubber Process Oil (RPO) is a highly refined and purified mineral oil that is specifically formulated to enhance the processability and properties of rubber compounds. It is derived from the distillation of crude oil and undergoes a rigorous refining process to remove impurities and undesirable components, resulting in a clear, colorless to pale yellow liquid with excellent stability and consistency.

Key Characteristics of Rubber Process Oil (RPO)

- High Viscosity: RPO exhibits high viscosity and lubricity, which helps to reduce friction and heat generation during the mixing and processing of rubber compounds, thereby improving workability and reducing processing times.

- Excellent Solvency: Its excellent solvency and compatibility with rubber polymers allow for better dispersion and distribution of fillers, plasticizers, and other additives, resulting in improved physical properties and performance of the finished rubber products.

- Low Volatility: RPO has low volatility and high flash point, which ensures safe handling, storage, and processing without the risk of flammability or environmental pollution.

- Chemical Stability: RPO is chemically stable and resistant to oxidation, which helps to prolong the service life of rubber products by preventing degradation, cracking, and premature aging due to exposure to heat, moisture, and UV radiation.

Types of Rubber Process Oil (RPO)

Rubber Process Oil (RPO) is classified into different types based on its viscosity, flash point, and aromatic content. Some of the common types of RPO include:

- Naphthenic RPO

Naphthenic RPO is derived from naphthenic crude oil and has a relatively low viscosity and high solvency. It is commonly used in the manufacturing of low-to-medium hardness rubber compounds, such as conveyor belts, hoses, and gaskets.

- Paraffinic RPO

Paraffinic RPO is derived from paraffinic crude oil and has a higher viscosity and lower solvency compared to naphthenic RPO. It is primarily used in the production of high-hardness rubber compounds, such as automotive tires, mechanical seals, and industrial belts.

- Aromatic RPO

Aromatic RPO contains a higher percentage of aromatic compounds and has excellent solvency and compatibility with rubber polymers. It is commonly used in specialty applications, such as high-performance tires, electrical insulation, and oil-resistant seals.

Benefits of Using Rubber Process Oil (RPO)

- Improved Processing

Rubber Process Oil (RPO) improves the processing and workability of rubber compounds by reducing viscosity, enhancing dispersion, and promoting better mixing and molding. This results in improved productivity, reduced energy consumption, and lower production costs for rubber manufacturers.

- Enhanced Physical Properties

RPO enhances the physical properties and performance of rubber products by improving tensile strength, tear resistance, abrasion resistance, and flexibility. This allows for the production of high-quality rubber products with superior durability, longevity, and performance in various applications.

- Cost-Effective

Despite its premium quality and exceptional performance, Rubber Process Oil (RPO) is a cost-effective additive for rubber manufacturers. Its ability to improve processability, enhance physical properties, and extend the service life of rubber products makes it a preferred choice for optimizing production processes and reducing overall production costs.

Applications of Rubber Process Oil (RPO)

Rubber Process Oil (RPO) has a wide range of applications across various industries due to its unique properties and versatile nature. Some of the common applications of RPO include:

- Tire Manufacturing

RPO is widely used in the manufacturing of automotive tires, motorcycle tires, and industrial tires to improve processing, enhance physical properties, and extend the service life of the tires. Its high viscosity, excellent solvency, and chemical stability make it an ideal additive for optimizing tire performance and durability.

- Hose and Belt Production

RPO is used in the production of various rubber hoses, belts, and conveyor systems to improve flexibility, enhance abrasion resistance, and extend the service life of the products. Its excellent solvency and compatibility with rubber polymers allow for better dispersion and distribution of additives, resulting in improved physical properties and performance.

- Seals and Gaskets

RPO is also used in the manufacturing of mechanical seals, gaskets, and O-rings to improve compression set, enhance chemical resistance, and extend the service life of the products. Its high viscosity, low volatility, and chemical stability make it an ideal additive for producing high-quality sealing solutions that can withstand extreme temperatures, pressures, and chemical exposures.

Peak Universal Business: Rubber Process Oil Supplier

When it comes to sourcing high-quality Rubber Process Oil (RPO), choosing the right supplier is crucial to ensuring quality, consistency, and reliability. Peak Universal Business is a leading supplier of RPO, offering a wide range of products to meet your specific needs.

- Quality Assurance

At Peak Universal Business, quality is our top priority. Our Rubber Process Oil (RPO) undergoes rigorous quality control processes to ensure that it meets the highest industry standards. You can trust our products to deliver exceptional performance and reliability for your specific applications.

- Competitive Pricing

We understand the importance of cost-effectiveness in today’s competitive market. That’s why we offer Rubber Process Oil (RPO) at competitive prices without compromising on quality. Our transparent pricing structure and flexible delivery options make us a preferred choice for businesses looking to optimize their supply chain and reduce costs.

- Exceptional Customer Service

At Peak Universal Business, we pride ourselves on providing exceptional customer service and support. Our team of experienced professionals is always ready to assist you with any inquiries, from product specifications to shipping and logistics. We strive to build long-lasting relationships with our clients by offering personalized solutions and attentive service that exceeds expectations.

Conclusion

Rubber Process Oil (RPO) is a versatile and high-quality material that offers numerous benefits for businesses across various industries. Its unique properties, including high viscosity, excellent solvency, and chemical stability, make it an ideal choice for a wide range of applications, from tire manufacturing and hose production to seal and gasket manufacturing.

When it comes to sourcing high-quality Rubber Process Oil (RPO), Peak Universal Business is your trusted partner for quality, reliability, and exceptional customer service. With competitive pricing, rigorous quality control, and a commitment to customer satisfaction, Peak Universal Business is the supplier you can rely on for all your RPO needs.

So, whether you are in the automotive, construction, manufacturing, or industrial sector, Peak Universal Business offers a wide range of high-quality Rubber Process Oil (RPO) products to meet your specific needs. Contact us today to learn more about our products and services and discover the difference that quality and reliability can make for your business.