Product Overview

Peak Universal Business, your trusted partner for high performance Drilling Fluids and Additives.

In the challenging world of oil and gas exploration, having the right drilling fluids and additives is crucial for success. At Peak Universal Business, we offer a comprehensive range of premium products designed to meet the demanding needs of the drilling industry.

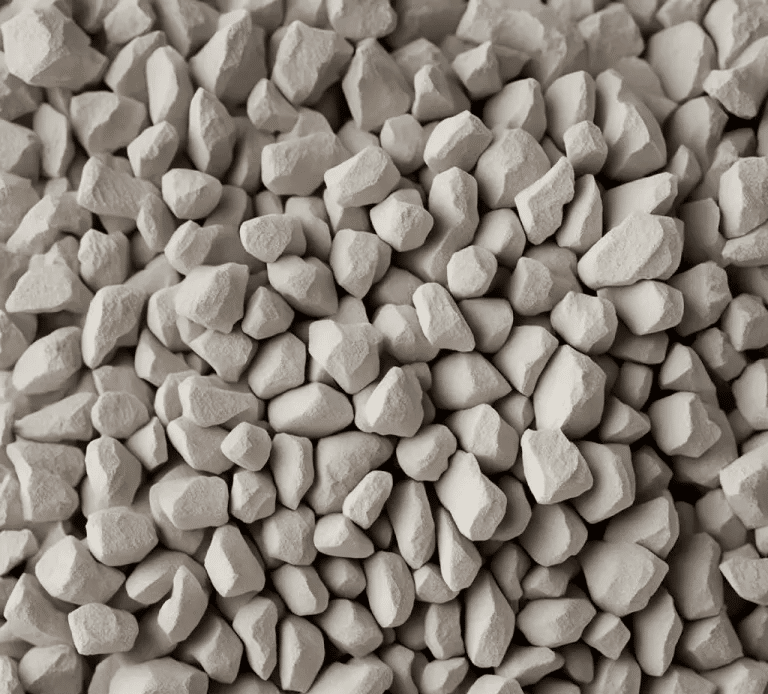

Our lineup includes a variety of essential additives such as Walnut Shell, Caustic Soda, Calcium Carbonate, Calcium Chloride, Bentonite, and Barite.

These additives play critical roles in enhancing drilling fluid properties, improving wellbore stability, controlling fluid density, and maximizing drilling efficiency.

Whether you’re drilling in challenging formations or tackling complex geological conditions, our Drilling Fluids and Additives are engineered to deliver superior performance and reliability. Backed by our commitment to quality and innovation, our products undergo rigorous testing to ensure compliance with industry standards and specifications.

The Role of Drilling Fluid in Oil and Gas Exploration:

Cooling and Lubrication, Pressure Control, Formation Stabilization, Cuttings Transport

-

Cooling and Lubrication:

One of the primary functions of drilling fluid is to cool and lubricate the drill bit and drilling assembly. The high-speed rotation of the drill bit generates friction and heat, which can lead to excessive wear and damage if not properly managed. Drilling fluid helps dissipate heat and reduce friction, extending the lifespan of the drill bit and improving drilling efficiency.

-

Pressure Control:

Drilling fluid plays a crucial role in controlling formation pressure and preventing blowouts during drilling operations. By exerting hydrostatic pressure on the formation, drilling fluid counteracts the natural pressure of reservoir fluids, ensuring well control and safety. Proper pressure management is essential to prevent formation damage, minimize risks, and maintain wellbore integrity.

-

Formation Stabilization:

In addition to cooling and pressure control, drilling fluid helps stabilize the wellbore and prevent collapses or cave-ins. The circulation of drilling fluid creates a hydraulic barrier that supports the walls of the borehole, preventing them from collapsing under the weight of overlying formations. This stability is crucial for the successful completion of drilling operations and the subsequent installation of casing and completion equipment.

-

Cuttings Transport:

As the drill bit penetrates the rock formations, it generates cuttings that must be removed from the wellbore to maintain drilling efficiency. Drilling fluid serves as a transport medium, carrying cuttings to the surface through the annular space between the drill string and the borehole wall. Efficient cuttings transport ensures clear visibility of the formation, facilitates logging and evaluation operations, and prevents debris buildup that can impede drilling progress.

Peak Universal Business strives to work for premium grade Drilling Fluids that optimize drilling operations, reduce costs, and enhance productivity.

Click below to get more information about the different type of Additives we offer: