Slack Wax: Uses, Applications, Advantages & Disadvantages.

What is the Application of Slack Wax? Slack wax, a byproduct derived from the refining of lubricating oil, is a versatile material with a wide range of applications. It is a crucial raw material in various industries due to its unique properties, which include a high oil content and a specific melting point range. This blog will provide an in-depth analysis of slack wax, covering its uses, applications, advantages, disadvantages, future prospects, and price factors, with a focus on Peak Universal Business as a reliable supplier.(What is the Application of Slack Wax? Cosmetics and Personal Care Products, Adhesives, Corrosion Inhibitors, Packaging, Agricultural Industry, Industrial Applications) and (Uses of Slack Wax: Candle Manufacturing, Rubber Industry, Textile Industry, Lubricants and Greases, Board Sizing, Emulsions and Coatings, Construction Industry, Polishes and Cleaners)

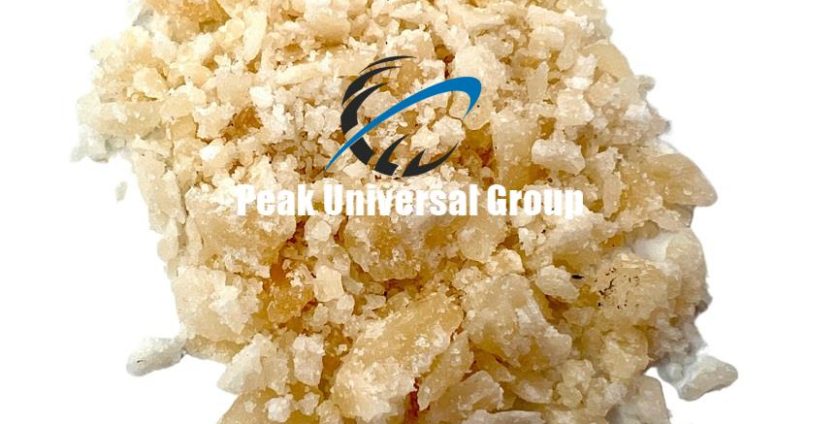

Understanding Slack Wax

Slack wax is a mixture of oil and wax that is produced during the refining of lubricating oil. It is derived from the de-oiling process of petroleum-based oils. The wax content in slack wax can vary, but it generally contains between 10% and 35% oil, with the rest being paraffin or microcrystalline wax. Slack wax is available in different grades, depending on the oil content and melting point.

Uses of Slack Wax

Slack wax has a variety of uses across different industries due to its versatile nature:

- Candle Manufacturing: One of the primary uses of slack wax is in the production of candles. The wax provides a smooth finish, a consistent burn rate, and can be easily colored or scented to create various types of candles, including pillar, taper, and container candles.

- Rubber Industry: In the rubber industry, slack wax is used as an additive to improve the processing and performance of rubber compounds. It acts as a release agent and helps to reduce the viscosity of the rubber, enhancing its flexibility and durability.

- Textile Industry: Slack wax is employed in the textile industry for the treatment of fabrics. It provides a soft, smooth finish to the fibers and helps in the process of fiber spinning and weaving.

- Board Sizing: It is used in the paper and board industry as a sizing agent. Slack wax helps to improve the water resistance and strength of paper and cardboard products, making them more durable and long-lasting.

- Lubricants and Greases: Slack wax serves as a base material for the production of lubricants and greases. It improves the lubricity and performance of these products, making them more effective in reducing friction and wear in machinery and automotive applications.

- Emulsions and Coatings: It is used in the formulation of various emulsions and coatings. Slack wax helps to enhance the properties of these products, including their adhesion, water resistance, and gloss.

- Construction Industry: Slack wax is utilized in the construction industry as a waterproofing agent for concrete and other building materials. It helps to improve the durability and water resistance of these materials, extending their lifespan.

- Polishes and Cleaners: Slack wax is an essential ingredient in the production of polishes and cleaners. It provides a protective coating, enhances shine, and improves the water resistance of various surfaces.

Applications of Slack Wax

The versatility of slack wax extends its applications to various fields:

- Cosmetics and Personal Care Products: Slack wax is used in the production of cosmetics and personal care products such as lotions, creams, and balms. It acts as an emollient and thickening agent, providing a smooth texture and enhancing the moisturizing properties of these (Cosmetics and Personal Care) products.

- Adhesives: In the adhesives industry, slack wax is used as a component in hot melt adhesives. It improves the viscosity and setting time of the adhesives, making them more effective for various applications, including packaging and woodworking.

- Corrosion Inhibitors: Slack wax is used as a corrosion inhibitor in metalworking and automotive applications. It provides a protective coating that prevents rust and corrosion on metal surfaces.

- Packaging: Slack wax is used in the packaging industry to improve the properties of packaging materials. It enhances the heat sealability and moisture resistance of packaging films, protecting the contents from environmental factors.

- Agricultural Industry: In the agricultural industry, slack wax is used as a coating for fertilizers and pesticides. It helps to improve the stability and effectiveness of these products, ensuring better crop yields and protection.

- Industrial Applications: Slack wax is used in various industrial applications, including the production of industrial coatings, inks, and resins. It enhances the properties of these products, improving their performance and durability.

Advantages of Slack Wax

Slack wax offers several advantages that make it a valuable material in various industries:

- Cost-Effective: Slack wax is a cost-effective material due to its abundance as a byproduct of the petroleum refining process. It provides an economical alternative to other waxes and additives.

- Versatility: Slack wax is highly versatile and can be used in a wide range of applications. Its unique properties make it suitable for various industrial processes, from candle making to rubber manufacturing.

- Improved Processing: In industries such as rubber and textiles, slack wax improves the processing efficiency by reducing viscosity and enhancing the flexibility of the materials.

- Enhanced Properties: Slack wax enhances the properties of the final products, including water resistance, durability, and surface finish. It provides a protective coating that improves the performance of various materials.

Disadvantages of Slack Wax

Despite its numerous advantages, slack wax has some limitations:

- High Oil Content: The high oil content in slack wax can be a disadvantage in certain applications. It may require additional processing to reduce the oil content and improve the wax quality.

- Variable Quality: The quality of slack wax can vary depending on the source and refining process. This variability can affect the consistency and performance of the final products.

- Environmental Concerns: As a petroleum-based product, slack wax raises environmental concerns regarding its sustainability and disposal. The production and disposal of slack wax contribute to carbon emissions and environmental pollution.

Future Prospects of Slack Wax

The future of slack wax looks promising, with ongoing research and development aimed at expanding its applications and improving its properties:

- Sustainable Alternatives: Researchers are exploring sustainable alternatives to traditional slack wax, focusing on bio-based and biodegradable options. The development of eco-friendly slack waxes from renewable resources aims to reduce the environmental impact of wax production and disposal.

- Advanced Applications: Innovations in material science and chemical engineering may lead to new applications of slack wax in high-tech industries, such as electronics and renewable energy. Slack wax with enhanced properties, such as improved thermal conductivity and electrical insulation, could find applications in advanced manufacturing processes.

- Improved Processing Techniques: Continuous improvements in the processing techniques of slack wax will enhance its quality and performance. Advanced refining methods and chemical modifications will result in slack waxes with tailored properties for specific applications.

Price Factors of Slack Wax

Several factors influence the price of slack wax:

- Raw Material Costs: The price of crude oil, the primary raw material for slack wax, significantly impacts its cost. Fluctuations in the global oil market affect the overall price of slack wax.

- Production Technology: Advanced production technologies can affect the overall cost of slack wax, with more efficient methods potentially reducing prices. Investments in state-of-the-art refining facilities and process optimization contribute to cost savings.

- Market Demand: The demand for slack wax in various industries influences its market price. High demand can lead to increased prices. Market trends, economic conditions, and industrial growth rates all play a role in determining the price of slack wax.

- Quality and Grade: Different grades and qualities of slack wax come with varying price points, with higher-quality waxes commanding premium prices. The specific application requirements and performance characteristics of slack wax influence its market value.

Peak Universal Business: Your Trusted Supplier of Slack Wax

As a leading supplier of high-quality Slack wax, Peak Universal Business is committed to providing reliable and consistent products for various industrial applications. With a focus on quality and customer satisfaction, Peak Universal Business ensures that its slack wax meets the highest industry standards. Whether you need slack wax for candle making, coatings, or rubber manufacturing, Peak Universal Business has the expertise and resources to meet your needs.

Conclusion

Slack wax is an essential material with diverse applications across various industries. Its unique properties make it invaluable in the production of candles, rubber, textiles, lubricants, and more. While it has some limitations, ongoing research and development promise to enhance its sustainability and performance.

Peak Universal Business stands as a reliable supplier of high-quality slack wax, ensuring that industries receive the best products for their specific needs. With the future looking bright for slack wax, it continues to be a critical component in many industrial applications, driving innovation and efficiency.

What is the Application of Slack Wax? Cosmetics and Personal Care Products, Adhesives, Corrosion Inhibitors, Packaging, Agricultural Industry, Industrial Applications

Uses of Slack Wax: Candle Manufacturing, Rubber Industry, Textile Industry, Lubricants and Greases, Board Sizing, Emulsions and Coatings, Construction Industry, Polishes and Cleaners

You can Read More about this product Here:

Slack Wax & Its Applications in Rubber Industry

Slack Wax for Rubber & Tire Industry

Properties and Uses of Heavy Slack Wax 8-12%

Slack Wax vs Petroleum Jelly: Its Uses & Applications

If You have any other Query or Question you want to ask, Please don’t hesitate to Contact Us

- 0 comment

Leave a Reply