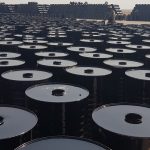

🛢️ What is Slow Curing Cutback Bitumen? – Applications, Specs & Benefits

Slow Curing (SC) Cutback Bitumen is a specially formulated bitumen product made by blending penetration-grade bitumen with slow-evaporating petroleum solvents such as diesel or gas oil. This formulation reduces viscosity, allowing it to be sprayed or applied at lower temperatures without compromising on performance. Its slow curing nature makes it ideal for deep penetration and extended working times in road construction and dust control applications.

In this article, we’ll cover the production, specifications, industrial applications, advantages, and key differences between SC cutbacks and other bitumen types—tailored for civil engineers, procurement teams, and asphalt professionals.

❓ What is Slow Curing Cutback Bitumen?

Slow Curing (SC) Cutback Bitumen is a liquid bitumen solution that remains workable for longer periods due to the use of slowly evaporating solvents. These solvents temporarily soften the bitumen, reducing its viscosity, and then gradually evaporate after application, allowing the bitumen to regain its original adhesive and cohesive strength.

It is especially effective where ambient temperatures are low or where longer curing time is required for maximum surface penetration and bonding.

🏭 Production of SC Cutback Bitumen

The production process involves:

-

Base Bitumen Selection: Typically 80/100 or 60/70 penetration-grade bitumen.

-

Blending with Solvent: The bitumen is blended with diesel or gas oil in controlled conditions to achieve the desired viscosity and curing characteristics.

-

Quality Control: Viscosity, flash point, and penetration tests are conducted to ensure specification compliance for various SC grades.

This process ensures that the final cutback product has the right balance of workability and long-term durability for field applications.

Types of Cutback Bitumen

Cutback bitumen is classified based on the type of solvent used and its rate of evaporation. The main types are:

1. Rapid Curing (RC) Cutback Bitumen: Uses a volatile solvent, resulting in fast evaporation and quick hardening.

2. Medium Curing (MC) Cutback Bitumen: Uses a medium-volatile solvent, providing a balance between working time and hardening rate.

3. Slow Curing (SC) Cutback Bitumen: Uses a slow-evaporating solvent, offering extended working time and gradual hardening.

Each type has specific properties and applications, with SC cutback bitumen being particularly useful for projects requiring extended working times.

📊 Technical Specifications of SC Cutback Bitumen

| Grade | Viscosity @ 60°C (cSt) | Flash Point (°C) | Distillation Residue (%) | Penetration of Residue (dmm) |

|---|---|---|---|---|

| SC-70 | 70–140 | >38 | >55 | 120–200 |

| SC-250 | 250–500 | >60 | >55 | 100–180 |

| SC-800 | 800–1600 | >65 | >55 | 90–160 |

| SC-3000 | 3000–6000 | >65 | >55 | 80–150 |

Understanding the specifications of Slow Curing Cutback Bitumen is crucial for selecting the right product for your application. Here are some common specifications:

1. Viscosity: Indicates the flow properties of the bitumen. SC cutback bitumen typically has a lower viscosity, making it easier to apply.

2. Flash Point: Indicates the temperature at which the bitumen produces enough vapours to ignite. SC cutback bitumen has a higher flash point, making it safer for high-temperature applications.

3. Penetration: Measures the hardness of the bitumen. SC cutback bitumen has a lower penetration value, indicating harder bitumen.

4. Ductility: Measures the bitumen’s ability to stretch without breaking. SC cutback bitumen has a high ductility value, indicating more flexible bitumen.

5. Softening Point: Indicates the temperature at which the bitumen softens. SC cutback bitumen has a higher softening point, suitable for high-temperature applications.

🔍 Key Properties of Slow Curing Cutback Bitumen

1. Extended Working Time:

Due to the slow evaporation rate of the solvent, SC cutback bitumen has a longer working time, allowing for more precise application.

2. Low Viscosity:

The addition of the solvent reduces the viscosity of the bitumen, making it easier to handle and apply at lower temperatures.

3. Gradual Hardening:

The slow evaporation process ensures a gradual hardening of the bitumen, resulting in a strong and durable bond.

4. Adhesive Properties:

SC cutback bitumen provides excellent adhesion to various substrates, ensuring materials stay in place.

5. Versatility:

Suitable for a wide range of applications, from road construction to waterproofing.

Applications of Slow Curing Cutback Bitumen

Slow Curing Cutback Bitumen is used in a variety of applications due to its unique properties. Here are some of the primary uses:

1. Road Construction

In road construction, SC cutback bitumen is used for various purposes, including priming, tack coating, and surface dressing.

Applications:

- Priming: SC cutback bitumen is used to prime porous surfaces such as base courses and subgrades, preparing them for subsequent layers of asphalt.

- Tack Coating: Applied as a tack coat between layers of asphalt to ensure a strong bond.

- Surface Dressing: Used for surface dressing of roads, providing a durable and skid-resistant surface.

2. Waterproofing

The excellent adhesive and waterproofing properties of SC cutback bitumen make it suitable for various waterproofing applications.

Applications:

- Foundation Waterproofing: Used to waterproof foundations, protecting them from water ingress and structural damage.

- Basement Waterproofing: Ensures basements remain dry, preventing water damage and mold growth.

- Roof Waterproofing: Applied to roofs to provide a durable and waterproof barrier.

🏗️ Industrial Applications of SC Cutback Bitumen

🚧 Prime Coating

SC bitumen is widely used as a prime coat on granular base courses before asphalt is laid. Its deep penetration improves adhesion between the base and the subsequent asphalt layers.

🌬️ Dust Suppression

Applied to unpaved roads or construction sites, SC cutback forms a cohesive film over loose particles, effectively controlling dust in dry and windy environments.

🛣️ Penetration Macadam

Used in road construction where stone layers are sprayed with SC bitumen and rolled to allow deep binding of aggregates. This method is cost-effective and durable for rural roads.

🧱 Soil Stabilization

In remote and underdeveloped areas, SC bitumen is mixed with native soil to create a stabilized, water-resistant base suitable for road building.

🏞️ Low Temperature Areas

Ideal for cold climate regions where traditional hot mix asphalts cannot be applied due to rapid cooling and workability issues.

Benefits of Using Slow Curing Cutback Bitumen

The use of SC cutback bitumen offers several significant benefits, making it a preferred choice for many projects.

1. Extended Working Time: The slow evaporation rate of the solvent provides a longer working time, allowing for more precise application and better results.

2. Ease of Application: The low viscosity of SC cutback bitumen makes it easy to handle and apply, even at lower temperatures.

3. Durability: The gradual hardening process ensures a strong and durable bond, providing long-lasting performance.

4. Versatility: Suitable for a wide range of applications, from road construction to waterproofing and industrial uses.

5. Cost-Effective: The extended working time and ease of application reduce labor costs and improve efficiency, making SC cutback bitumen a cost-effective choice.

✅ Key Advantages

-

⏳ Extended Workability Time: Perfect for large or remote projects.

-

🔥 No Need for Heating: Reduces energy consumption and equipment use.

-

🌱 Eco-Compatible: Can be applied with minimal environmental disruption.

-

💰 Cost-Effective: Low initial cost and reduced labor requirements.

-

🏗️ Deep Penetration: Improves strength and longevity of base layers.

1. Cost-Effective: The extended working time and ease of application reduce labor costs and improve efficiency, making SC cutback bitumen a cost-effective choice.

2. Environmentally Friendly: SC cutback bitumen is a sustainable material that can be recycled and reused in various applications.

3. Versatile: Suitable for a wide range of applications, from road construction to waterproofing and industrial uses.

4. Reliable Performance: Provides consistent and reliable performance in various environmental conditions.

5. Ease of Use: Available in various forms, including liquid and semi-solid, making it easy to handle and apply.

🔧 SC vs MC vs RC Cutback Bitumen – Comparison Table

| Property | SC Bitumen | MC Bitumen | RC Bitumen |

| Solvent Type | Diesel/Gas Oil | Kerosene | Naphtha/Gasoline |

| Curing Rate | Slow | Medium | Rapid |

| Application | Prime coat, dust control | Patching, base prep | Surface treatments |

| Climate Suitability | Cold/Wet Areas | Temperate Zones | Hot/Dry Regions |

| Health/Safety Risks | Low | Medium | High (flammable) |

Why Choose Peak Universal Business as Your Slow Curing Cutback Bitumen Supplier?

When it comes to sourcing high-quality Slow Curing Cutback Bitumen, Peak Universal Business stands out as the ideal supplier. Here are some reasons why:

1. Quality Assurance: Peak Universal Business ensures that its SC cutback bitumen meets the highest quality standards, providing reliable and consistent materials for your projects.

2. Competitive Pricing: They offer competitive prices without compromising on quality, ensuring you get the best value for your investment.

3. Reliable Supply Chain: With a robust supply chain, Peak Universal Business guarantees timely delivery, ensuring your projects proceed without delay.

4. Expertise and Support: Their team of experts is always available to provide guidance and support, helping you select the right products for your specific needs.

5. Customer Satisfaction: Committed to customer satisfaction, Peak Universal Business offers exceptional service and support, ensuring a seamless procurement experience.

❓ FAQ about Slow Curing Cutback Bitumen

❓ What is slow curing cutback bitumen used for?

It is used for prime coating, dust suppression, penetration macadam, and base stabilization—especially in low-temperature or remote areas.

❓ How long does slow curing bitumen take to dry?

Depending on temperature and wind conditions, SC bitumen can take from several hours to a few days to fully cure.

❓ Is SC bitumen environmentally friendly?

While it contains petroleum solvents, SC bitumen has lower volatility and can be applied in a controlled manner to reduce environmental impact.

❓ Can SC cutback be stored long-term?

Yes, when stored in sealed containers away from direct sunlight and ignition sources, SC bitumen can remain usable for several months.

❓ Is SC bitumen safe to use in populated areas?

Due to its low volatility and relatively safe flash point, it is suitable for use near residential or urban zones with proper precautions.

📌 Conclusion

Slow Curing Cutback Bitumen offers a unique combination of workability, penetration capability, and extended setting time—making it a versatile choice for a wide range of infrastructure projects. Whether used in prime coats, dust control, or cold region construction, its slow evaporation and deep bonding performance make it indispensable in modern road engineering and civil works.

Understanding the detailed properties, applications, and benefits of SC cutback bitumen can help you make informed decisions when selecting materials for your projects.

By choosing Peak Universal Business as your supplier, you can be confident in receiving high-quality SC cutback bitumen, competitive pricing, reliable delivery, and expert support. Whether you need SC cutback bitumen for road construction, waterproofing, or industrial applications, Peak Universal Business has the expertise and resources to meet your needs. Experience the difference in quality and service by partnering with Peak Universal Business for your Slow Curing Cutback Bitumen requirements.

📣 Call to Peak Universal Business

🔍Looking for a dependable SC Cutback Bitumen supplier?

Get reliable, high-quality products backed by lab certification and timely logistics.

📌 Contact Us For:

-

Material Safety Data Sheets (MSDS) & TDS

-

Bulk supply in drums or tankers

-

Expert recommendations for your project

👉 Request a Quote Today

📧 Email: [email protected]

📞 Phone: +971 4 878 2031

🌐 Visit: PUBLtd. Cutback Bitumen

If You have any other Query or Question you want to ask, Please don’t hesitate to Contact Us.

You can Read More about Our products Here :

- 0 comment

Leave a Reply