The Versatility and Applications of Paraffin Wax in Various Industries

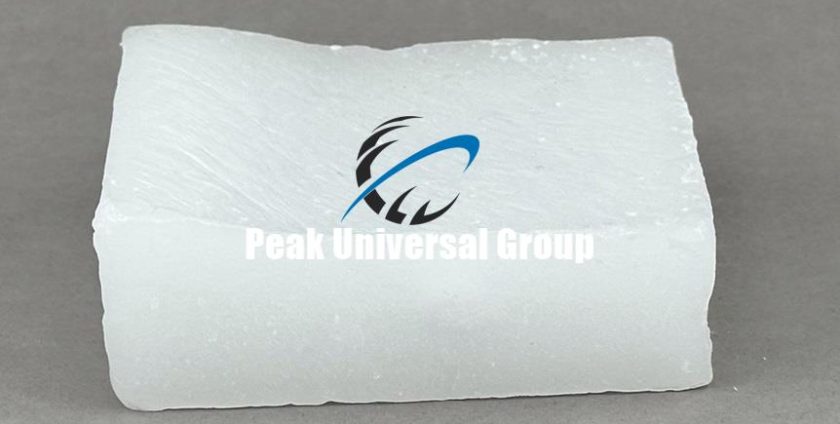

Paraffin wax is a white or colorless soft solid derived from saturated hydrocarbons. It is commonly used in a variety of applications due to its non-reactive and non-toxic nature. Paraffin wax is typically produced through the refining of crude oil, and its composition can vary depending on the source and processing methods used.

Paraffin wax is a versatile material that finds applications across various industries due to its unique properties. Derived from petroleum, coal, or oil shale, paraffin wax is composed of a mixture of hydrocarbon molecules, making it a highly adaptable substance.

This blog will delve into the uses, types, applications, advantages, disadvantages, and future prospects of this products, emphasizing why Peak Universal Business is the ideal supplier for all your paraffin wax needs.

Properties:

- Melting Point: Ranges between 46°C and 68°C

- Boiling Point: Around 370°C

- Density: Approximately 0.9 g/cm³

- Solubility: Insoluble in water but soluble in benzene, ether, and certain esters

- Color: White to colorless

- Odor: Odorless

- Chemical Stability: Highly stable and inert

Types of Paraffin Wax

It can be classified into different types based on its refining process and properties:

1. Fully Refined

Fully refined paraffin wax has the highest purity level, with oil content typically below 0.5%. It is extensively used in applications requiring high-quality wax, such as cosmetics, pharmaceuticals, and food packaging.

2. Semi-Refined

Semi-refined paraffin wax has an oil content ranging from 0.5% to 1.5%. It is commonly used in applications where the highest purity is not essential, such as in candles and certain industrial applications.

3. Scale Wax

Scale wax is less refined and has a higher oil content, usually above 1.5%. It is primarily used in industrial applications where high purity is not required.

Uses and Applications:

Paraffin wax is widely used across various industries due to its versatility. Here are some of the key applications:

1. Candle Making

Paraffin wax is one of the primary materials used in candle making due to its ability to burn cleanly and consistently. It is used to create a variety of candle types, including:

- Pillar Candles: Solid and long-lasting

- Taper Candles: Slim and elegant

- Votive Candles: Small and cylindrical

- Container Candles: Poured into jars or other containers

2. Packaging

Paraffin wax is used in the packaging industry to provide a moisture barrier and enhance the appearance of products. Common applications include:

- Food Packaging: Coating for cheese, fruits, and vegetables

- Corrugated Boxes: Wax coating for moisture resistance

- Paper Coating: Provides a smooth, glossy finish

3. Cosmetics and Personal Care

Paraffin wax is a key ingredient in various cosmetics and personal care products due to its emollient properties. It is used in:

- Lotions and Creams: Provides a smooth texture and helps retain moisture

- Lip Balms: Protects and hydrates lips

- Hair Removal Products: Used in wax strips and hot wax formulations

4. Pharmaceuticals

In the pharmaceutical industry, paraffin wax is used as a base for ointments and creams, providing a protective barrier and aiding in the delivery of active ingredients.

5. Industrial Applications

Paraffin wax is used in several industrial applications, including:

- Lubrication: Acts as a lubricant for machinery and equipment

- Corrosion Protection: Coating for metal surfaces to prevent rust

- Adhesives and Sealants: Provides flexibility and stability

6. Agriculture

Paraffin wax is used in agriculture to coat seeds, providing a protective barrier against moisture and pests, and enhancing seed longevity.

7. Rubber and Tires

In the rubber industry, paraffin wax is used as an anti-ozonant to prevent cracking and extend the lifespan of rubber products, including tires.

Advantages:

1. Versatility

Paraffin wax can be used in a wide range of applications, making it a versatile material suitable for various industries.

2. Stability

Paraffin wax is chemically stable and non-reactive, making it safe for use in food, cosmetics, and pharmaceutical applications.

3. Cost-Effectiveness

Paraffin wax is relatively inexpensive compared to other waxes, such as beeswax or soy wax, making it a cost-effective choice for many applications.

4. High Melting Point

The high melting point of paraffin wax makes it suitable for applications requiring heat resistance, such as candle making and industrial uses.

5. Moisture Resistance

Paraffin wax provides an excellent moisture barrier, making it ideal for packaging and protective coatings.

Disadvantages:

1. Environmental Impact

Its derived from petroleum, a non-renewable resource, and its production and use can have environmental impacts, including carbon emissions and waste generation.

2. Health Concerns

When burned, It can release harmful compounds such as toluene and benzene, which can pose health risks. This is a concern particularly for indoor air quality.

3. Limited Biodegradability

Its not readily biodegradable, which can be an issue in applications where environmental sustainability is a priority.

Future Prospects:

1. Sustainable Alternatives

Research is ongoing to develop sustainable alternatives to paraffin wax, including bio-based waxes derived from renewable resources. These alternatives aim to reduce the environmental impact of wax production and use.

2. Advanced Applications

Innovations in material science are expanding the applications of paraffin wax. For example, paraffin wax is being explored for use in energy storage systems due to its high heat capacity.

3. Enhanced Properties

Future developments may focus on enhancing the properties of paraffin wax through additives and modifications, improving its performance in various applications.

4. Recycling and Reuse

Efforts are being made to develop recycling and reuse methods for paraffin wax, reducing waste and promoting a circular economy.

Price Factors:

Several factors influence the price of paraffin wax, including:

1. Crude Oil Prices

As paraffin wax is derived from crude oil, fluctuations in crude oil prices directly impact the cost of paraffin wax.

2. Refining Costs

The cost of refining and processing paraffin wax affects its final price. Higher purity levels and advanced refining techniques can increase costs.

3. Supply and Demand

Market dynamics of supply and demand play a significant role in determining the price of paraffin. Increased demand or reduced supply can lead to higher prices.

4. Geopolitical Factors

Geopolitical events and trade policies can influence the availability and cost of paraffin on the global market.

5. Transportation Costs

The cost of transporting paraffin from production facilities to end-users can affect its final price, especially for international shipments.

Why Choose Peak Universal Business as Your Paraffin?

Peak Universal Business stands out as a leading supplier of high-quality paraffin wax. Here are some reasons why you should choose them for your paraffin needs:

1. Quality Assurance

Peak Universal Business is committed to providing products that meet the highest quality standards. Their paraffin wax undergoes rigorous testing to ensure it meets the required specifications and performs reliably in various applications.

2. Industry Expertise

With extensive experience in the industry, Peak Universal Business has a deep understanding of the diverse applications and requirements of paraffin wax. They can offer expert guidance and support to help you find the right solution for your needs.

3. Reliable Supply Chain

Peak Universal Business has a robust supply chain that ensures timely delivery of products. Their global reach and efficient logistics enable them to meet the demands of clients worldwide.

4. Customer-Centric Approach

Customer satisfaction is a top priority for Peak Universal Business. They strive to build long-term relationships with their clients by offering personalized service, competitive pricing, and reliable support.

5. Sustainable Practices

Peak Universal Business is committed to sustainable practices, including the use of eco-friendly materials and production processes. They are dedicated to minimizing their environmental impact and contributing to a greener future.

Conclusion

Paraffin wax is a versatile and essential material used across various industries due to its unique properties and wide range of applications. While it offers numerous benefits, such as versatility, stability, and cost-effectiveness, it also has some disadvantages, including environmental impact and health concerns. However, ongoing research and innovation promise to address these issues and enhance the future prospects of paraffin wax.

When looking for a reliable supplier, Peak Universal Business stands out with their commitment to quality, industry expertise, and customer-centric approach. Whether you need paraffin for candle making, packaging, cosmetics, or industrial applications, Peak Universal Business is your trusted partner for high-quality solutions.

You can Read More about this product Here:

How to check the quality of paraffin?

If You have any other Query or Question you want to ask, Please don’t hesitate to Contact Us.

- 0 comment

Leave a Reply