Slack Wax: Its Key Properties, Applications & Benefits in Textile Industry

Slack Wax in Textile Industry – Slack wax, a byproduct of the petroleum refining process, has found its way into various industries due to its versatile properties. One of the significant industries benefiting from slack wax is the Textile industry. This blog will delve into the detailed uses, applications, and advantages of slack wax in textiles. (Benefits of Using Slack Wax in the Textile Industry:Cost-Effective, Versatility, Improved Product Quality, Environmental Benefits) We will also explore why Peak Universal Business stands out as the premier supplier of this essential material. Slack wax is a crude wax obtained during the refining of lubricating oil. It consists of a mixture of oil and wax, typically containing 5-30% oil. The properties of slack wax can vary depending on the refining process and the source of crude oil. (Yarn Manufacturing, Fabric Finishing, Dyeing Process, Textile Lubricants),

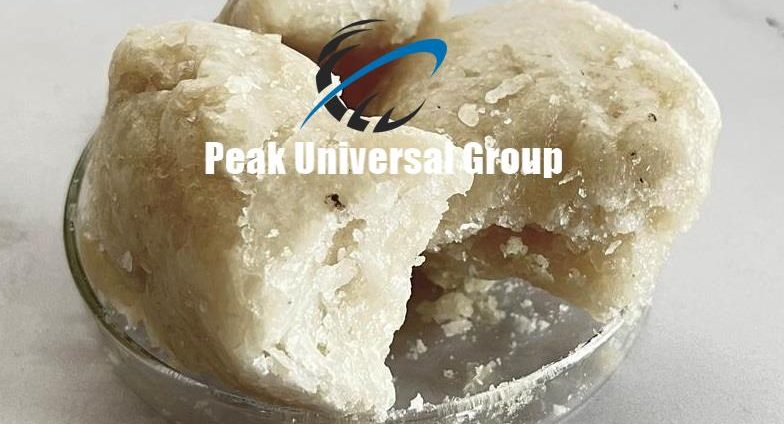

Key Properties of Slack Wax

- Oil Content: Varies between 5-30%, influencing its physical characteristics.

- Melting Point: Typically ranges from 45°C to 65°C.

- Color: Usually, pale yellow to dark brown.

- Odor: Mild to moderate, depending on oil content and refining process.

- Consistency: Semi-solid at room temperature, becoming liquid when heated.

Slack Wax in the Textile Industry

The textile industry leverages the unique properties of slack wax for various applications. From yarn manufacturing to fabric finishing, slack wax plays a crucial role in enhancing the quality and performance of textile products.

1. Yarn Manufacturing

In the yarn manufacturing process, slack wax is used as a lubricant to improve the efficiency and quality of yarn production.

Uses:

- Spinning: Reduces friction between fibers during spinning, resulting in smoother yarn.

- Twisting: Facilitates the twisting process by reducing resistance, leading to stronger yarn.

Advantages:

- Enhanced Yarn Quality: Results in fewer breaks and imperfections.

- Increased Efficiency: Reduces wear and tear on machinery, extending its lifespan.

2. Fabric Finishing

Slack wax is used in fabric finishing to impart desirable properties to the final textile products.

Uses:

- Softening: Provides a soft and smooth feel to fabrics.

- Waterproofing: Enhances the water-resistant properties of fabrics.

- Coating: Used in the coating process to improve the durability and appearance of fabrics.

Advantages:

- Improved Texture: Results in fabrics that are pleasant to touch and wear.

- Enhanced Durability: Protects fabrics from environmental factors like moisture and UV radiation.

- Aesthetic Appeal: Gives fabrics a lustrous and appealing finish.

3. Dyeing Process

In the dyeing process, slack wax is used to achieve uniform color distribution and improve dye uptake.

Uses:

- Dispersant: Helps in the even distribution of dyes across the fabric.

- Penetration Enhancer: Improves the penetration of dyes into fibers.

Advantages:

- Consistent Color: Results in vibrant and uniform colors.

- Efficient Dyeing: Reduces the amount of dye required, making the process more economical.

4. Textile Lubricants

Slack wax is an essential component in the formulation of textile lubricants used in various stages of textile manufacturing.

Uses:

- Fiber Processing: Lubricates fibers to reduce friction and static during processing.

- Weaving: Lubricates looms and other weaving equipment to ensure smooth operation.

Advantages:

- Reduced Friction: Minimizes wear and tear on machinery and fibers.

- Enhanced Performance: Increases the efficiency and lifespan of textile machinery.

Benefits of Using Slack Wax in the Textile Industry

The use of slack wax in the textile industry offers several benefits that enhance the overall quality and efficiency of textile manufacturing processes.

1. Cost-Effective

Slack wax is relatively inexpensive compared to other specialized lubricants and finishing agents. This cost-effectiveness makes it an attractive option for textile manufacturers looking to reduce production costs without compromising quality.

2. Versatility

The versatility of slack wax allows it to be used in various stages of textile production, from yarn manufacturing to fabric finishing. Its adaptability makes it a valuable resource for textile manufacturers.

3. Improved Product Quality

By reducing friction and enhancing the properties of fibers and fabrics, slack wax helps produce higher-quality textile products. This leads to increased customer satisfaction and loyalty.

4. Environmental Benefits

Many slack wax products are biodegradable and environmentally friendly, making them a sustainable choice for textile manufacturers. Using slack wax can help companies meet environmental regulations and reduce their carbon footprint.

Why Choose Peak Universal Business as Your Slack Wax Supplier?

When it comes to sourcing slack wax, Peak Universal Business stands out as a trusted and reliable supplier. Here are some reasons why:

1. High-Quality Products: Peak Universal Business ensures that their slack wax meets stringent quality standards, providing you with consistent and reliable materials.

2. Competitive Pricing: They offer competitive prices without compromising on quality, ensuring you get the best value for your investment.

3. Reliable Supply Chain: With a robust supply chain, Peak Universal Business guarantees timely delivery, ensuring your projects proceed without delay.

4. Expertise and Support: Their team of experts is always available to provide guidance and support, helping you select the right products for your specific needs.

5. Customer Satisfaction: Committed to customer satisfaction, Peak Universal Business offers exceptional service and support, ensuring a seamless procurement experience.

Applications of Slack Wax Beyond Textiles

While slack wax is extensively used in the textile industry, its applications extend to several other industries as well.

1. Rubber Industry

Slack wax is used in the rubber industry as a processing aid and lubricant. It helps improve the processing and performance of rubber products.

2. Candle Manufacturing

Slack wax is a key ingredient in candle manufacturing, providing a slow and consistent burn rate.

3. Wood Processing

In wood processing, slack wax is used as a coating and preservative, protecting wood from moisture and enhancing its appearance.

4. Emulsions and Polishes

Slack wax is used in the production of emulsions and polishes, providing a smooth and shiny finish to various surfaces.

Conclusion

Slack wax is an invaluable resource in the textile industry, offering numerous benefits that enhance the quality and efficiency of textile manufacturing processes. From yarn manufacturing to fabric finishing, slack wax plays a crucial role in improving the performance and appearance of textile products.

By choosing Peak Universal Business as your supplier, you gain access to high-quality slack wax, competitive pricing, reliable delivery, and expert support. This ensures that your textile manufacturing processes are efficient, cost-effective, and environmentally friendly. The versatility of slack wax also extends to other industries, making it a valuable resource for various applications. Whether you’re in the textile, rubber, candle, wood processing, or polish industry, slack wax provides the reliable performance you need.

Choose Peak Universal Business for your Slack Wax needs and experience the difference in quality and service. With their expertise and commitment to excellence, you can be confident that your projects will benefit from the best materials available.

You can Read More about Slack Wax Here:

What is the Application of Slack Wax?

Slack Wax & Its Applications in Rubber Industry

How Heavy Slack wax 2-5% Oil Content is manufactured?

Slack Wax for Rubber & Tire Industry

- 0 comment

Leave a Reply