How Gilsonite is Produced & Used in Daily Life

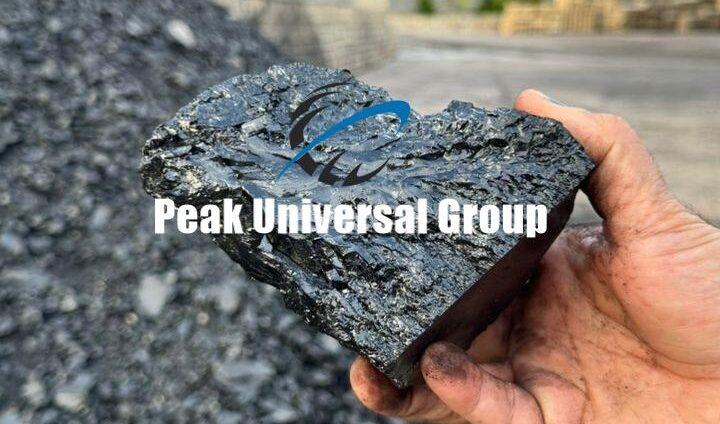

How Gilsonite is Produced? – Gilsonite, also known as Natural Bitumen, is a naturally occurring, solid hydrocarbon that is increasingly recognized for its diverse applications across various industries. Its unique properties make it an invaluable resource for enhancing products and processes, thereby improving various aspects of our daily lives.

In this comprehensive exploration, we dive into the complicate production processes of Gilsonite, its extensive uses of Gilsonite, and how it significantly contributes to our everyday experiences. We also highlight Peak Universal Business, a leading supplier committed to delivering high-quality Gilsonite products.

Understanding Gilsonite: What is Natural Bitumen?

Gilsonite, or Natural Bitumen, is a form of Asphalt found in nature, primarily in the United States. It is a brittle, glossy black substance composed mainly of hydrocarbons. Its unique molecular structure, which includes high levels of asphaltenes and resins, imparts it with distinct properties such as high solubility in aromatic solvents, thermal stability, and excellent binding capabilities.

How Gilsonite is Produced?

1. Exploration and Mining

How Gilsonite is Produced? The journey of Gilsonite begins with the exploration of natural deposits. Geologists identify potential sites based on geological surveys and sampling. Once a viable deposit is located, mining operations commence. Gilsonite is typically found in vertical veins, making it accessible through underground mining techniques.

2. Extraction

Mining Gilsonite involves drilling and blasting to break up the ore, which is then transported to the surface. Traditional mining tools and modern machinery work in tandem to ensure efficient extraction. The extracted Gilsonite is then transported to processing facilities.

3. Processing and Refining

At the processing plant, Gilsonite undergoes several stages of refinement to enhance its purity and usability:

- Crushing and Grinding: The raw Gilsonite ore is crushed and ground into a fine powder to facilitate further processing.

- Separation: Impurities such as rocks and soil are separated from the Gilsonite using various mechanical and chemical processes.

- Grading: The refined Gilsonite is graded based on particle size and purity to meet specific industry standards and requirements.

4. Packaging and Distribution

The final product is packaged in various forms, including powder, granular, and lump forms, to cater to different industrial applications. Peak Universal Business ensures that the packaging adheres to international standards to maintain product quality during transportation and storage.

Extensive Uses of Gilsonite in Various Industries

Uses of Gilsonite – Gilsonite’s versatility and unique properties make it suitable for a wide range of applications across multiple industries. Here, we explore its major uses of Gilsonite and how it enhances our daily lives:

1. Asphalt and Road Construction

- Road Paving: Gilsonite is widely used as an additive in asphalt formulations to improve the durability, elasticity, and resistance of road surfaces. Road constructed with Gilsonite-modified asphalt exhibit superior performance, reduced maintenance costs, and longer lifespans.

- Sealants and Binders: It acts as an effective binder and sealant, enhancing the adhesion properties of asphalt mixtures and preventing moisture penetration, which leads to pavement deterioration.

2. Inks and Coatings

- Printing Inks: Gilsonite serves as a critical ingredient in the production of high-quality printing inks. Its high carbon content and solubility in aromatic solvents make it ideal for producing black inks with excellent gloss and durability.

- Coatings: It is also used in protective coatings for metals and wood, offering enhanced weather resistance, UV stability, and improved adhesion properties.

3. Oil and Gas Industry

- Drilling Fluids: In the oil and gas sector, Gilsonite is added to drilling fluids to improve their stability and performance. It helps to reduce fluid loss, strengthen wellbore walls, and enhance the overall efficiency of drilling operations.

- Cementing: It is also used in well cementing processes to enhance the sealing properties of cement slurries, ensuring better zonal isolation and well integrity.

4. Foundry Industry

- Sand Additive: In foundries, Gilsonite is used as an additive in sand molds to improve the surface finish of cast metal products. It helps to prevent defects such as sand inclusions and improves the overall quality of castings.

5. Chemical Industry

- Adhesives and Sealants: The adhesive and cohesive properties of Gilsonite make it a valuable ingredient in the production of various adhesives and sealants. It enhances the bonding strength and durability of adhesive products.

- Rubber and Plastics: It is also used as a reinforcing filler in rubber and plastic formulations, improving their mechanical properties and resistance to wear and tear.

Enhancing Daily Life with Gilsonite

Gilsonite’s impact on daily life extends beyond industrial applications. Its contributions can be seen in several everyday products and processes:

1. Improved Road Infrastructure

The uses of Gilsonite in road construction results in smoother, more durable roads with fewer potholes and cracks. This translates to safer, more comfortable travel experiences and reduced vehicle maintenance costs.

2. High-Quality Printed Materials

Printing inks containing Gilsonite produce sharper, more vibrant prints, enhancing the quality of newspapers, magazines, packaging materials, and other printed products.

3. Efficient Oil and Gas Extraction

Gilsonite’s role in drilling fluids and cementing processes ensures more efficient and safer oil and gas extraction operations. This contributes to a stable energy supply and helps meet the growing demand for fossil fuels.

4. Superior Coatings and Sealants

Protective coatings and sealants containing Gilsonite offer enhanced durability and longevity for various surfaces, including metal structures, wooden furniture, and infrastructure components, extending their service life and reducing maintenance efforts.

Advanced Industrial Applications of Gilsonite

How Gilsonite is Produced? As industries evolve and technology advances, the applications of Gilsonite continue to expand into more specialized and high-tech areas. Let’s explore some advanced industrial applications where Gilsonite is making a significant impact:

1. Advanced Polymer Composites

Gilsonite is increasingly being used as an additive in advanced polymer composites, particularly in the automotive and aerospace industries. Its inclusion enhances the thermal stability, mechanical strength, and overall performance of composite materials. This leads to lighter, stronger, and more durable components in vehicles and aircraft, contributing to fuel efficiency and improved safety.

2. Enhanced Drilling Technologies

In the Oil and Gas industry, advanced drilling technologies require materials that can withstand extreme conditions. Gilsonite’s unique properties make it ideal for use in high-performance drilling fluids and muds that can operate effectively at high temperatures and pressures. This advancement allows for deeper and more efficient drilling operations, reducing costs and increasing the yield of oil and gas wells.

3. High-Performance Coatings

High-performance coatings that incorporate Gilsonite offer superior protection against corrosion, abrasion, and environmental degradation. These coatings are used in critical infrastructure such as pipelines, bridges, and industrial equipment, ensuring long-term durability and reducing maintenance costs. The development of nanocoatings with Gilsonite further enhances its protective properties, offering cutting-edge solutions for various industrial applications.

4. Renewable Energy Sector

In the renewable energy sector, particularly in the production of solar panels and wind turbines, Gilsonite is used to improve the efficiency and longevity of these technologies. It is utilized in the formulation of coatings and adhesives that enhance the performance and durability of solar panels and wind turbine blades, contributing to the overall sustainability and cost-effectiveness of renewable energy solutions.

Environmental Impacts of Gilsonite

While Gilsonite offers numerous benefits, it is crucial to consider its environmental impact throughout its lifecycle, from extraction to end-use. Understanding these impacts allows for the development of sustainable practices and technologies to mitigate any negative effects.

1. Mining and Extraction

The extraction of Gilsonite involves mining activities that can have environmental implications, such as habitat disruption, soil erosion, and water pollution. Implementing responsible mining practices, such as minimizing land disturbance, using environmentally friendly extraction techniques, and rehabilitating mined areas, can significantly reduce these impacts.

2. Processing and Refining

The processing and refining of Gilsonite require energy and water resources, potentially leading to emissions and wastewater generation. Adopting energy-efficient technologies, recycling water, and treating emissions can help mitigate these environmental impacts. Additionally, developing cleaner and more efficient refining processes can further enhance the sustainability of Gilsonite production.

3. Use and Disposal

The uses of Gilsonite in various applications generally has a low environmental impact compared to alternative materials. However, the disposal of products containing Gilsonite should be managed properly to prevent environmental contamination. Recycling and repurposing Gilsonite-containing materials can reduce waste and promote a circular economy.

Future Prospects of Gilsonite

The future of Gilsonite looks promising, with ongoing research and development driving new applications and improving existing ones. Here are some potential future prospects for Gilsonite:

1. Sustainable and Eco-Friendly Products

The push towards sustainability and eco-friendliness in various industries presents an opportunity for Gilsonite to be incorporated into greener products. Research is being conducted on developing bio-based and biodegradable composites that include Gilsonite, offering environmentally friendly alternatives to traditional materials.

2. Advanced Material Science

Advancements in material science continue to unlock new potential for Gilsonite. Innovations in nanotechnology and polymer science are leading to the development of advanced materials with enhanced properties. Gilsonite’s unique characteristics make it a valuable component in these cutting-edge materials, opening up new possibilities in electronics, construction, and healthcare.

3. Enhanced Oil Recovery

In the oil and gas sector, enhanced oil recovery (EOR) techniques are being explored to maximize the extraction of oil from existing reservoirs. Gilsonite-based additives are being researched for their potential to improve the efficiency of EOR processes, increasing the yield and extending the life of oil fields.

4. Infrastructure Development

As global infrastructure continues to expand, the demand for durable and high-performance construction materials will grow. Gilsonite’s role in producing superior asphalt and coatings positions it as a key material in future infrastructure projects. Innovations in road construction and maintenance using Gilsonite will contribute to more sustainable and resilient infrastructure systems.

Sourcing Gilsonite from Peak Universal Business: Quality and Reliability

Peak Universal Business stands as a trusted supplier of high-quality Gilsonite products, offering tailored solutions to meet the specific needs of various industries. With a commitment to quality assurance, technical expertise, and customer satisfaction, Peak Universal Business ensures that customers receive reliable and consistent products. Their comprehensive supply chain management and adherence to international standards make them a preferred partner for sourcing Gilsonite.

Frequently Asked Questions (FAQ)

Is Gilsonite eco-friendly?

Yes, Gilsonite is a naturally occurring mineral and is considered less harmful than synthetic petroleum-based additives.

How is Gilsonite transported after mining?

After grading and packing, Gilsonite is shipped globally in bags, bulk trucks, or containers for use in industrial plants.

Can Gilsonite be used in DIY or home applications?

Not typically. It’s an industrial material used in commercial production of sealants, inks, pavements, and coatings.

Where is most Gilsonite mined?

The largest known reserves are in Utah, USA, but it’s also mined in Iran, Turkey, and other countries with natural bitumen deposits.

Conclusion

How Gilsonite is Produced? Gilsonite, or Natural Bitumen, is a remarkable natural resource with a wide range of applications that significantly enhance various aspects of our daily lives. From improving road infrastructure and printing quality to optimizing oil and gas extraction and providing superior protective coatings, Gilsonite’s versatility and unique properties make it an invaluable material across numerous industries.

As we look to the future, the potential for sustainable and advanced applications of Gilsonite continues to grow, promising further enhancements to our industrial processes and everyday experiences. Sourcing from reputable suppliers like Peak Universal Business ensures access to high-quality Gilsonite products, driving innovation and efficiency in industrial processes while maintaining a commitment to sustainability.

By embracing the potential of Gilsonite and investing in its responsible production and application, we can continue to unlock its benefits for future generations, paving the way for a more sustainable and advanced industrial landscape.

Learn how Gilsonite is mined and processed, and explore its everyday applications in roads, inks, sealants, and beyond. Discover its impact on modern life.

You can Read More about Gilsonite Here:

Gilsonite: Its Uses, Applications

Difference between Bitumen and Gilsonite

How Gilsonite is used in Advanced Roofing & Sealing Materials?

Gilsonite details and features

📣 Call to Peak Universal Business

👉 Want to Source Gilsonite Directly from the Production Line?

Gain access to premium-grade Gilsonite processed with precision—from raw ore extraction to micronized powder—ensuring purity, consistency, and performance.

📞 Contact our production experts today to learn more about our mining practices, processing standards, and export-ready packaging.

🛒 Request a Production Sample or Quotation →🌐 Visit: https://publtd.com

📧 Email: [email protected]

📞 Phone: +971 4 878 2031

We offer high-purity Gilsonite with custom ash levels and mesh sizes. Request a quote, technical datasheet, or sample for your industry needs today. If You have any other Query or Question you want to ask, Please don’t hesitate to Contact Us.

- 0 comment

Leave a Reply