Fully Refined Paraffin Wax: Its Manufacturing Process, Types, Uses & Benefits

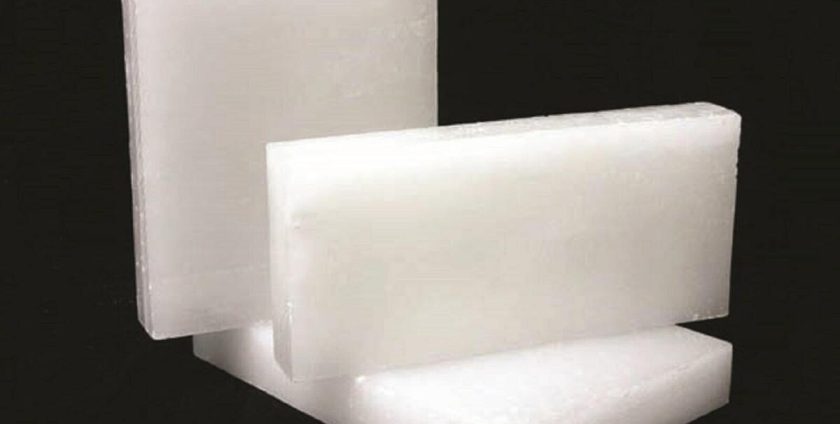

Fully refined paraffin wax is a high-quality, purified wax product derived from petroleum. It is known for its versatility and is used in various industries, from cosmetics and pharmaceuticals to food packaging and candle making.

In this comprehensive blog, we will delve into the intricate manufacturing process of fully refined paraffin wax, explore its different types, uses, applications, advantages, disadvantages, and future prospects. With Peak Universal Business as a trusted supplier, you can be assured of top-notch quality and reliable supply for all your paraffin wax needs.

( How Fully Refined Paraffin Wax is Manufactured: Crude Oil Extraction and Refining, Dewaxing, Hydrotreating, Clay Treatment, Distillation and Polishing )

Manufacturing Process of Fully Refined Paraffin Wax

How Fully Refined Paraffin Wax is Manufactured: Crude Oil Extraction and Refining, Dewaxing, Hydrotreating, Clay Treatment, Distillation and Polishing

1. Crude Oil Extraction and Refining

The journey of fully refined paraffin wax begins with the extraction of crude oil. The extracted crude oil undergoes an initial refining process to separate various components, including lubricating oil base stocks and waxy distillates. This process involves distillation and solvent extraction to isolate the waxy fractions.

2. Dewaxing

Dewaxing is a crucial step in the production of fully refined paraffin wax. The waxy distillates obtained from crude oil refining contain a mixture of paraffin wax and oil. To separate the wax, the distillates are cooled to a low temperature, causing the wax to crystallize. The crystallized wax is then separated from the oil using filtration or centrifugation.

3. Hydrotreating

The separated wax undergoes hydrotreating to remove impurities, including sulfur, nitrogen, and oxygen compounds. Hydrotreating involves reacting the wax with hydrogen in the presence of a catalyst at high temperatures and pressures. This process not only purifies the wax but also enhances its stability and color.

4. Clay Treatment

To achieve a high level of refinement, the wax is subjected to clay treatment. In this process, the wax is mixed with activated clay and heated to a specific temperature. The activated clay adsorbs any remaining impurities, including color bodies and trace metals. The treated wax is then filtered to remove the clay.

5. Distillation and Polishing

The final step in the manufacturing process involves distillation and polishing. The wax is distilled to achieve the desired melting point and purity. It is then polished using additional filtration techniques to remove any residual impurities and achieve a clear, odorless, and colorless product.

Types of Fully Refined Paraffin Wax

Fully refined paraffin wax is available in various grades, each tailored to specific applications:

1. Low Melting Point Wax (45-55°C)

- Uses: Candle making, coating for paper and cardboard, and as a lubricant additive.

- Advantages: Easy to melt and mix with other ingredients, suitable for applications requiring lower melting temperatures.

2. Medium Melting Point Wax (55-65°C)

- Uses: Cosmetics, pharmaceuticals, and food packaging.

- Advantages: Balanced melting point, good stability, and suitable for a wide range of applications.

3. High Melting Point Wax (65-75°C)

- Uses: Industrial applications, electrical insulation, and rubber processing.

- Advantages: High thermal stability, excellent hardness, and suitable for high-temperature applications.

Uses and Applications of Fully Refined Paraffin Wax

1. Candle Making

Fully refined paraffin wax is extensively used in candle making due to its excellent burning properties, ability to hold fragrances, and clean-burning characteristics. It is the preferred choice for both scented and unscented candles.

2. Cosmetics and Pharmaceuticals

In the cosmetics industry, paraffin wax is used in the formulation of creams, lotions, and lip balms. It provides a smooth texture, acts as a moisture barrier, and enhances the stability of products. In pharmaceuticals, it is used in ointments, therapeutic wax treatments, and as a coating for tablets.

3. Food Packaging

Paraffin wax is used as a coating for food packaging materials such as paper, cardboard, and certain types of plastic. It provides a moisture barrier, enhances the shelf life of food products, and ensures food safety.

4. Industrial Applications

In industrial settings, fully refined paraffin wax is used for applications such as electrical insulation, lubricants, rubber processing, and as a release agent in various manufacturing processes. It is also used in the production of matches, polishes, and adhesives.

5. Agriculture

Paraffin wax is used in agriculture for grafting trees and protecting plants from pests and diseases. It is applied as a coating to seal grafts and prevent moisture loss.

Advantages of Fully Refined Paraffin Wax

- Purity: Fully refined paraffin wax is highly purified, making it suitable for applications requiring stringent quality standards.

- Versatility: Its wide range of melting points and properties make it suitable for diverse applications.

- Stability: It has excellent thermal and chemical stability, ensuring long-lasting performance.

- Odorless and Colorless: The refining process removes impurities, resulting in an odorless and colorless product, ideal for cosmetics and food applications.

- Cost-Effective: Paraffin wax is relatively inexpensive compared to other waxes, providing cost savings in various applications.

Disadvantages of Fully Refined Paraffin Wax

- Non-Renewable: Derived from petroleum, fully refined paraffin wax is a non-renewable resource, raising concerns about sustainability.

- Environmental Impact: The production and disposal of paraffin wax can have negative environmental impacts, including greenhouse gas emissions and potential pollution.

- Limited Biodegradability: Paraffin wax is not easily biodegradable, which can lead to environmental persistence.

Future Prospects of Fully Refined Paraffin Wax

1. Sustainable Alternatives

The future of fully refined paraffin wax may see a shift towards more sustainable alternatives. Researchers are exploring bio-based waxes derived from renewable resources such as vegetable oils and animal fats. These alternatives aim to reduce the environmental impact and dependence on fossil fuels.

2. Innovative Applications

Advancements in technology and research are likely to lead to innovative applications of paraffin wax. New formulations and blends may enhance its properties and expand its use in industries such as electronics, renewable energy, and advanced manufacturing.

3. Improved Refining Techniques

Future prospects also include the development of improved refining techniques that minimize environmental impact and enhance the efficiency of the production process. Innovations in catalyst technology, energy efficiency, and waste management can contribute to a more sustainable manufacturing process.

Price Factors of Fully Refined Paraffin Wax

The price of fully refined paraffin wax is influenced by several factors:

1. Crude Oil Prices

As paraffin wax is derived from petroleum, fluctuations in crude oil prices directly impact its cost. Higher crude oil prices typically lead to increased production costs for paraffin wax.

2. Demand and Supply

The balance of demand and supply in the market affects the price of paraffin wax. High demand and limited supply can drive prices up, while an oversupply can lead to lower prices.

3. Quality and Grade

The specific grade and quality of paraffin wax also influence its price. Higher grades with greater purity and specific properties may command a premium price.

4. Manufacturing Costs

The costs associated with refining, processing, and packaging paraffin wax contribute to its final price. Advances in refining technology and efficiency can help reduce production costs.

5. Transportation and Logistics

Transportation and logistics costs, including shipping, storage, and handling, play a role in the overall price of paraffin wax. Proximity to manufacturing facilities and efficient logistics networks can impact costs.

Why Choose Peak Universal Business as Your Fully Refined Paraffin Wax Supplier?

Choosing the right supplier for fully refined paraffin wax is crucial for ensuring the quality and consistency of your products. Peak Universal Business stands out as a top supplier for several reasons:

1. Uncompromised Quality

Peak Universal Business is committed to providing the highest quality fully refined paraffin wax. Our products undergo rigorous quality control processes to ensure they meet the strictest industry standards. This means you can rely on our wax for its purity, stability, and performance across a wide range of applications.

2. Extensive Industry Experience

With years of experience in the wax industry, Peak Universal Business has a deep understanding of the specific needs and challenges faced by different sectors. Our expertise enables us to offer tailored solutions and support, ensuring that our paraffin wax meets your precise requirements.

3. Reliable Supply Chain

We pride ourselves on maintaining a robust and reliable supply chain. Our strategic partnerships with leading refineries and efficient logistics network ensure timely delivery and consistent availability of fully refined paraffin wax, no matter where you are located.

4. Competitive Pricing

At Peak Universal Business, we strive to offer competitive pricing without compromising on quality. By optimizing our production processes and supply chain management, we provide cost-effective solutions that help you manage your budget while still receiving top-notch products.

5. Exceptional Customer Service

Customer satisfaction is at the heart of our business. Our dedicated customer service team is always ready to assist you with any inquiries, provide technical support, and address your concerns promptly. We build long-term relationships with our clients based on trust, reliability, and excellence.

6. Sustainable Practices

We are committed to sustainability and environmental responsibility. Our refining processes are designed to minimize environmental impact, and we are continuously exploring ways to incorporate more sustainable practices into our operations.

Conclusion

Fully refined paraffin wax is a versatile and widely used product with numerous applications across various industries. Its manufacturing process involves multiple steps to ensure high purity and quality. While it offers many advantages, including stability, versatility, and cost-effectiveness, it also presents challenges related to environmental impact and sustainability.

Future prospects for fully refined paraffin wax include the development of sustainable alternatives, innovative applications, and improved refining techniques. Understanding the factors that influence its price can help businesses make informed decisions when sourcing paraffin wax.

With Peak Universal Business as a reliable supplier, you can trust in the quality and consistency of fully refined paraffin wax for all your needs.

How Fully Refined Paraffin Wax is Manufactured? Crude Oil Extraction and Refining, Dewaxing, Hydrotreating, Clay Treatment, Distillation and Polishing

You can Read More about this product Here:

How Gilsonite is Produced? and Its Uses to Enhance our Daily Lives

Fully Refined Paraffin Wax & Its Applications

How to check the quality of paraffin?

Fully Refined Paraffin Wax for Beauty & Cosmetics Industry

Paraffin Wax in Rubber Industry Applications

If You have any other Query or Question you want to ask, Please don’t hesitate to Contact Us.

- 0 comment

Leave a Reply