Ground Calcium Carbonate (GCC): Technical Overview, Industrial Applications, Performance Characteristics, and Supplier Insights

Ground Calcium Carbonate (GCC) is a widely used industrial mineral valued for its stability, purity, and cost efficiency. Because of its versatile properties, GCC is incorporated into major industries such as paper, plastics, coatings, construction chemicals, adhesives, and rubber. Additionally, its dependable performance makes it essential for manufacturing environments where precision and consistency matter.

This technical guide presents a complete overview of GCC, including its production, functional characteristics, performance behavior, and sourcing considerations.

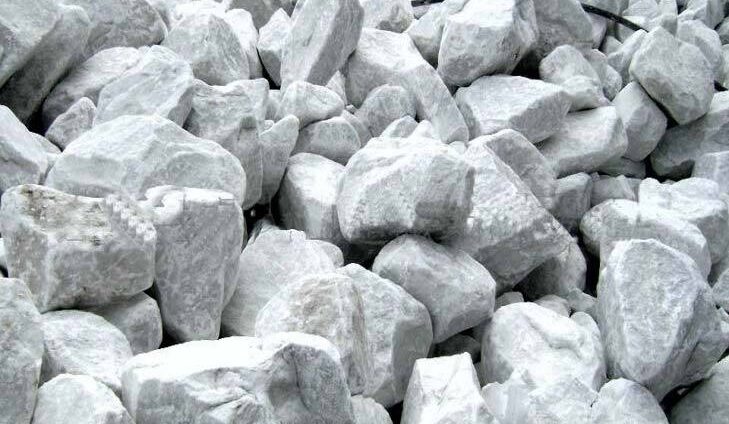

1. Technical Definition and Production of Ground Calcium Carbonate

Ground Calcium Carbonate (GCC) is produced by mechanically processing naturally occurring high-purity limestone. Initially, the limestone is extracted and crushed into smaller fragments. After that, it is ground into fine powder and classified to achieve the desired particle size distribution. Finally, the material may be surface-treated to improve dispersion in specific applications.

Production Steps

-

Extraction: Limestone is mined from certified deposits with high CaCO₃ content.

-

Primary Crushing: Material is reduced to a workable size.

-

Fine Grinding: Specialized mills reduce particle size to micrometer levels.

-

Air Classification: Particles are separated into grades.

-

Surface Coating (optional): Stearic acid or similar agents enhance polymer compatibility.

As a result, Ground Calcium Carbonate can be engineered to meet highly specific industrial needs.

2. Material Properties of Ground Calcium Carbonate (GCC)

Because GCC is reliable and chemically stable, it provides consistent performance across several applications.

2.1 Particle Size Distribution (PSD)

PSD is a critical property because it directly influences opacity, reinforcement, viscosity, flow behavior, and surface finish.

-

Ultrafine GCC: <1–3 µm

-

Fine GCC: 5–10 µm

-

Coarse GCC: 20–100 µm

Consequently, manufacturers can select precise grades to optimize product performance.

2.2 Brightness and Whiteness

GCC commonly offers brightness values between 95–98%.

Moreover, high brightness significantly improves optical properties in paper, plastics, and decorative coatings.

2.3 Chemical Composition

Typical GCC contains 97–99% calcium carbonate.

Because of its low impurity levels, it remains stable and compatible with both organic and inorganic chemical systems.

2.4 Morphology and Surface Characteristics

GCC features a naturally rhombohedral crystal structure.

Therefore, it provides excellent dispersion, low oil absorption, and improved smoothness in finished products.

2.5 Mohs Hardness

With a hardness of 3, GCC is soft enough to minimize machinery wear.

At the same time, it contributes moderate reinforcement in composites.

2.6 Thermal Behavior

GCC decomposes at temperatures above 800°C.

Thus, it remains stable during most industrial processing conditions.

3. Industrial Applications of Ground Calcium Carbonate

Ground Calcium Carbonate Uses: Since GCC offers both functional and economic advantages, it plays an essential role in multiple industries.

3.1 Paper and Pulp Industry

GCC is extensively used in alkaline papermaking systems.

Functions

-

Acts as a filler to enhance opacity, brightness, and sheet uniformity.

-

Functions as a coating pigment to improve printability and ink absorption.

Benefits

-

Reduces wood-pulp consumption.

-

Improves printing clarity and optical performance.

-

Lowers overall production cost.

Consequently, GCC is a preferred choice for both coated and uncoated paper grades.

3.2 Plastics, Polymers, and Composite Materials

GCC is one of the most important functional fillers for polymer processing.

Applications

-

PVC pipe, cable, profiles

-

HDPE and PP products

-

Masterbatches

-

Automotive plastics

Performance Advantages

-

Improves stiffness and dimensional stability

-

Enhances heat resistance and impact behavior

-

Reduces polymer usage, thereby lowering material cost

-

Improves surface finish and thermal conductivity

Furthermore, surface-treated GCC grades provide superior dispersion and bonding in polymers.

3.3 Paints, Coatings, and Inks

GCC functions as an extender pigment and performance enhancer.

Functional Benefits

-

Increases opacity and brightness

-

Controls rheology for smoother application

-

Enhances durability and abrasion resistance

-

Reduces TiO₂ consumption

As a result, GCC contributes to high-quality, cost-efficient coating formulations.

3.4 Construction and Building Materials

GCC improves mechanical and rheological properties in both cement-based and polymer-based systems.

Applications

-

Tile adhesives

-

Mortars and plasters

-

Concrete additives

-

Skim coats and putties

Advantages

-

Enhances compressive strength

-

Reduces cracking and shrinkage

-

Improves workability and flow

-

Provides a smoother final finish

Therefore, it is widely used in modern construction chemistry.

3.5 Rubber and Elastomers

Ground Calcium Carbonate Uses as a reinforcing filler in several rubber products.

Benefits

-

Enhances stiffness and modulus

-

Improves abrasion resistance

-

Provides dimensional stability

-

Reduces production cost

End Uses

-

Tires

-

Automotive rubber components

-

Belts and hoses

-

Footwear

Consequently, GCC helps manufacturers achieve competitive cost-performance ratios.

3.6 Agriculture and Environmental Use

GCC also supports agricultural productivity.

Applications

-

Soil pH adjustment

-

Fertilizer additive

-

Animal feed supplement

Additionally, it acts as a neutralizing agent in acidic soils, helping improve crop performance.

4. Key Advantages of Ground Calcium Carbonate

Because GCC combines functionality with affordability, it is considered one of the most efficient industrial minerals.

4.1 Cost Efficiency

-

Reduces dependency on expensive raw materials

-

Enhances formulation economics

4.2 High Compatibility

-

Chemically inert and easy to integrate into formulations

4.3 Predictable Behavior

-

Consistent PSD and brightness ensure stable performance

4.4 Sustainability

-

Naturally sourced

-

Energy-efficient production

-

Low environmental impact

Together, these advantages make GCC indispensable in modern manufacturing.

5. Selecting a Reliable GCC Supplier

Quality consistency is essential for industrial applications. When evaluating suppliers, manufacturers typically consider:

Choosing a reliable supplier is essential for ensuring product quality.

Key Criteria

-

Purity and brightness consistency

-

Precise particle size control

-

Availability of specialized grades

-

Technical support for formulation optimization

-

Reliable logistics and global supply capacity

Therefore, manufacturers should evaluate suppliers based on both technical capability and long-term reliability.

6. Peak Universal Business: Reliable GCC Supply Partner

Peak Universal Business offers a comprehensive portfolio of Ground Calcium Carbonate grades tailored to industrial requirements. The company focuses on delivering:

Product Advantages

-

High whiteness and brightness values

-

Controlled particle size distributions

-

Low oil absorption and high purity

-

Surface-modified GCC options for polymers

Industry Support

-

Technical guidance for formulation integration

-

Customized solutions based on application needs

-

Consistent quality and global delivery capabilities

Peak Universal Business ensures dependable supply for sectors such as plastics, paper, paints, rubber, construction, and agriculture—making it a trusted choice for manufacturers seeking quality and reliability.

Conclusion- Ground Calcium Carbonate Uses

Ground Calcium Carbonate (GCC) remains an essential raw material across multiple industrial sectors due to its consistent performance, cost-efficiency, and broad application range. Its controlled particle size distribution, high brightness, chemical stability, and compatibility with various formulation systems make it a dependable choice for manufacturers seeking both functional enhancement and economic advantage.

Moreover, as industries continue to prioritize product optimization and sustainable material selection, GCC offers a reliable solution that supports these evolving requirements.

For organizations requiring consistent quality and supply reliability, partnering with an experienced and technically capable supplier is critical. Peak Universal Business delivers high-purity Ground Calcium Carbonate with precise specifications, robust quality control, and flexible grade options tailored to diverse industrial needs.

Through its technical expertise and dependable global distribution capabilities, the company ensures manufacturers receive materials that enhance process efficiency, product performance, and long-term operational value.

Ultimately, Ground Calcium Carbonate will continue to play a pivotal role in modern manufacturing. Its versatility, availability, and performance benefits position it as a strategic mineral solution for industries focused on innovation, efficiency, and sustainable growth.

With Peak Universal Business as a trusted supplier, you can unlock the full potential of GCC and achieve success in your projects.

Ground Calcium Carbonate Uses: Particle Size Distribution, Brightness and Whiteness, Paper Industry, Plastics Industry, Paints and Coatings, Construction Materials

You can Read More about Our products Here:

What is drilling fluid additive?

What are the 7 functions of Drilling Fluid Mud?

Applications of Barite in Drilling Mud

If You have any other Query or Question you want to ask, Please don’t hesitate to Contact Us.

- 0 comment

Leave a Reply