What is Carbon Black used for?

- Category: Blogs, Drilling Fluids Additive

- 0 comment

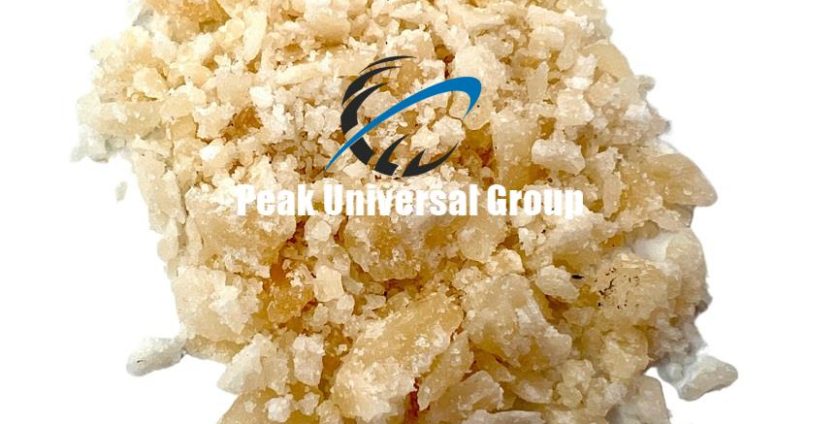

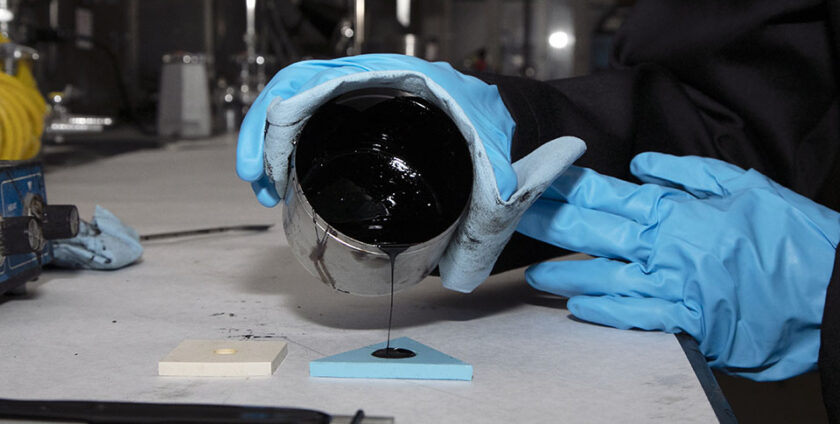

The Versatility of Carbon Black and Carbon Powder: Applications, Advantages, and Market Dynamics Carbon Black, also known as Carbon Powder, is a fine black powder consisting of elemental carbon. It is produced through the incomplete combustion of heavy petroleum products such as FCC tar, coal tar, and ethylene cracking tar. This material is renowned for its high surface-area-to-volume ratio, albeit lower than that of activated carbon. Peak Universal Business is…

Read more →