- Color: Typically yellow to brown

- Odor: Mild petroleum smell

- Melting Point: 45-65°C (113-149°F), depending on the specific oil content

- Density: Approximately 0.90 g/cm³

- Viscosity: Medium to high, influenced by oil content

- Solubility: Insoluble in water, soluble in organic solvents like benzene and toluene

Manufacturing of Heavy Slack Wax (2-5% Oil Content)

Production Methods: Vacuum Distillation, Solvent Dewaxing, Filtration and Separation

The production of heavy slack wax involves several key steps within the petroleum refining process. The primary methods include:

- Vacuum Distillation

- Solvent Dewaxing

- Filtration and Separation

1. Vacuum Distillation

The initial step in producing heavy slack wax is vacuum distillation, a process that separates crude oil into different fractions based on their boiling points.

- Crude Oil Heating: Crude oil is heated to a high temperature in a distillation column. Under atmospheric pressure, this would cause thermal cracking, but vacuum distillation allows separation at lower temperatures.

- Fractional Distillation: The heated crude oil is introduced into a vacuum distillation tower, where it separates into various fractions. The heavier fractions, including waxy distillates, are collected at the bottom.

2. Solvent Dewaxing

Solvent dewaxing is the key process for extracting wax from the heavy distillate fractions obtained from vacuum distillation.

- Mixing with Solvents: The waxy distillates are mixed with solvents such as methyl ethyl ketone (MEK) or toluene, which dissolve the oil and separate it from the wax.

- Cooling: The mixture is cooled to very low temperatures, causing the wax to crystallize and precipitate out of the solution.

- Filtration: The solidified wax is separated from the solvent-oil mixture using filtration. The filtrate (oil and solvent) is collected separately.

3. Filtration and Separation

Filtration and Separation – After the solvent dewaxing process, the wax is further processed to achieve the desired oil content and purity.

- Filtering: The slack wax is filtered to remove any remaining solvent and oil impurities.

- Centrifugation: In some cases, centrifugation is used to further purify the wax by spinning it at high speeds to separate out any remaining oil.

- Final Refining: The wax undergoes final refining steps, such as bleaching and deodorizing, to improve its color and odor.

Uses and Applications of Heavy Slack Wax (2-5% Oil Content)

Heavy slack wax with 2-5% oil content is used across a wide range of industries due to its unique properties. Here are some of its most common uses and applications:

1. Candle Manufacturing

Slack wax is widely used in the candle industry as a primary ingredient for making various types of candles.

Applications in Candle Manufacturing

- Container Candles: Heavy slack wax is often used to make container candles. Its medium melting point and oil content provide good burn characteristics and fragrance retention.

- Pillar Candles: It is also used for making pillar candles, where its hardness and structural integrity help maintain the candle’s shape during burning.

- Blending: Slack wax can be blended with other waxes, such as paraffin wax or stearic acid, to achieve specific melting points and performance characteristics.

2. Rubber Industry

In the rubber industry, slack wax serves as a processing aid and lubricant.

Applications in the Rubber Industry

- Processing Aid: Slack wax is used to improve the processing and extrusion of rubber compounds. It reduces viscosity and enhances the flow properties of rubber during molding and extrusion processes.

- Internal Lubricant: It acts as an internal lubricant, reducing friction and wear during the mixing and molding of rubber, which extends the life of processing equipment.

- Anti-Tack Agent: Slack wax is applied to rubber sheets to prevent them from sticking together, facilitating easier handling and storage.

3. Coatings and Emulsions

Heavy slack wax is an essential ingredient in various coatings and emulsions used in industrial applications.

Applications in Coatings and Emulsions

- Wood Coatings: It is used in wood coatings to provide a protective layer that enhances the durability and appearance of wood products. The wax offers water repellency and a smooth finish.

- Paper Coatings: Slack wax is used in paper coatings to impart water resistance and improve the texture and printability of paper products.

- Emulsions: It is used to produce wax emulsions that serve as coating agents for textiles, leather, and other materials. These emulsions provide flexibility, water resistance, and improved handling characteristics.

4. Textile Industry

Slack wax finds applications in the textile industry for fabric finishing and processing.

Applications in the Textile Industry

- Softening Agent: It is used as a softening agent to improve the hand feel and drape of fabrics, making them more comfortable to wear.

- Water Repellency: Slack wax is applied to textiles to impart water-repellent properties, making them suitable for outdoor and weather-resistant applications.

- Finishing Agent: It is used in fabric finishing processes to enhance the appearance, durability, and performance of textiles.

5. Adhesives and Sealants

Heavy slack wax is used in the production of adhesives and sealants to enhance their performance and application properties.

Applications in Adhesives and Sealants

- Hot Melt Adhesives: Slack wax improves the viscosity and thermal stability of hot melt adhesives, ensuring smooth application and strong bonding.

- Sealants: It provides flexibility, durability, and resistance to environmental factors in sealants, ensuring long-lasting sealing performance.

6. Industrial Lubricants

Slack wax is used as a base material in the formulation of industrial lubricants.

Applications in Industrial Lubricants

- Lubricating Greases: It is used in the production of lubricating greases, providing a consistent texture and improving the grease’s performance under high temperatures and pressures.

- Metalworking Fluids: Slack wax is used in metalworking fluids to reduce friction and wear during machining and forming processes, extending tool life and improving surface finishes.

- Mold Release Agents: It is used as a mold release agent in various manufacturing processes, preventing products from sticking to molds and facilitating easy removal.

7. Personal Care Products

In the personal care industry, slack wax is used in various formulations to enhance product performance.

Applications in Personal Care Products

- Lotions and Creams: Slack wax is used in lotions and creams to provide a smooth, silky texture and improve the product’s stability and spreadability.

- Lip Balms and Lipsticks: It is used in lip balms and lipsticks to provide structure and enhance the product’s moisture-retaining properties.

- Hair Care Products: Slack wax is used in hair care products, such as pomades and styling waxes, to provide hold and shine while conditioning the hair.

Benefits of Using Heavy Slack Wax (2-5% Oil Content)

Heavy slack wax offers numerous benefits across various industries due to its unique properties and versatility. Here are some of the key benefits of using heavy slack wax:

1. Cost-Effectiveness

Heavy slack wax is a cost-effective material compared to other types of waxes. Its lower production costs and versatile applications make it an economical choice for various industries.

2. Enhanced Product Performance

Slack wax enhances the performance of end products by providing properties such as water repellency, flexibility, and improved texture. This results in high-quality products that meet industry standards and consumer expectations.

3. Versatility

Heavy slack wax is a highly versatile material that can be used in a wide range of applications across various industries. Its ability to enhance different properties makes it a valuable additive in candles, coatings, adhesives, textiles, and more.

4. Improved Processing Efficiency

Slack wax improves the processing efficiency of various materials by reducing friction, improving flow properties, and preventing sticking. This leads to smoother manufacturing processes and reduced wear on machinery.

5. Environmental Benefits

Using slack wax can lead to environmental benefits by reducing the need for synthetic additives and chemicals. Its use in coatings, adhesives, and lubricants can also reduce the environmental impact of these products by providing natural water repellency and reducing the release of harmful substances.

Peak Universal Business: Your Trusted Supplier of Heavy Slack Wax (2-5% Oil Content)

Peak Universal Business is a leading supplier of high-quality heavy slack wax with 2-5% oil content. With a commitment to excellence and customer satisfaction, they offer a wide range of slack wax products tailored to meet the specific needs of their clients.

Why Choose Peak Universal Business?

- Quality Assurance: Peak Universal Business ensures the highest quality standards in their slack wax products, guaranteeing consistency and reliability.

- Technical Expertise: Their team of experts provides technical support and guidance, helping customers optimize the use of slack wax in their applications.

- Customized Solutions: They offer customized slack wax solutions to meet the unique requirements of different industries and applications.

- Sustainability Focus: Peak Universal Business is committed to sustainability and environmentally responsible practices in the production and supply of slack wax.

Conclusion

Heavy slack wax (2-5% oil content) is a versatile and valuable material with a wide range of uses and applications across various industries. Its unique properties, such as medium melting point, flexibility, and water repellency, make it suitable for enhancing the performance of candles, coatings, adhesives, rubber, textiles, and more. The manufacturing process of slack wax involves several steps, including vacuum distillation, solvent dewaxing, and filtration, to achieve the desired oil content and purity.

Peak Universal Business stands out as a reliable supplier of high-quality slack wax, offering technical expertise, customized solutions, and a commitment to sustainability. By understanding the properties, production process, and diverse applications of heavy slack wax, manufacturers can make informed decisions to enhance their products and processes, ultimately achieving greater success in their industries. (Production Methods: Vacuum Distillation, Solvent Dewaxing, Filtration and Separation)

You can Read More about this product Here:

Properties and Uses of Heavy Slack Wax 8-12%

What is the Application of Slack Wax?

How Heavy Slack Wax 5 to 8% Oil Content is Manufactured

Slack Wax & Its Applications in Rubber Industry

If You have any other Query or Question you want to ask, Please don’t hesitate to Contact Us

Heavy Slack Wax (2-5% Oil Content): Manufacturing, Uses, Applications, and Benefits

How Heavy Slack wax 2-5% Oil Content is manufactured? Heavy Slack Wax, with 2-5% oil content, is a crucial material in various industries due to its unique properties and versatility. This blog will delve into the detailed manufacturing process of heavy slack wax, its numerous uses, applications, and benefits. We will also highlight Peak Universal Business as a reliable supplier of this essential material. (Production Methods: Vacuum Distillation, Solvent Dewaxing, Filtration and Separation)

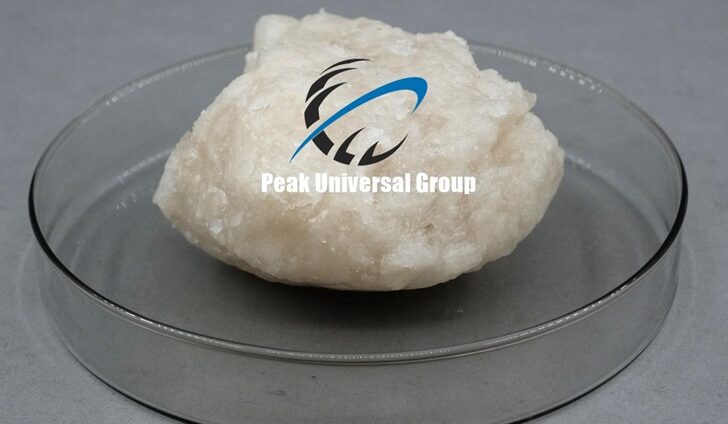

What is Heavy Slack Wax?

Heavy slack wax is a byproduct of the petroleum refining process, specifically obtained during the production of lubricating oils. It is a semi-solid substance composed of a mixture of paraffin wax and oil. The “2-5% oil content” refers to the proportion of oil present in the slack wax, which significantly influences its properties and applications.

Chemical Composition

Heavy slack wax consists primarily of long-chain hydrocarbons. The exact composition can vary, but typically includes:

- Paraffin Wax: Hydrocarbon chains (C20-C50) that provide structural stability and high melting points.

- Oil: A smaller proportion of lighter hydrocarbons (C10-C20) that impart flexibility and lower the melting point.

Physical Properties

- Color: Typically yellow to brown

- Odor: Mild petroleum smell

- Melting Point: 45-65°C (113-149°F), depending on the specific oil content

- Density: Approximately 0.90 g/cm³

- Viscosity: Medium to high, influenced by oil content

- Solubility: Insoluble in water, soluble in organic solvents like benzene and toluene

Manufacturing of Heavy Slack Wax (2-5% Oil Content)

Production Methods: Vacuum Distillation, Solvent Dewaxing, Filtration and Separation

The production of heavy slack wax involves several key steps within the petroleum refining process. The primary methods include:

- Vacuum Distillation

- Solvent Dewaxing

- Filtration and Separation

1. Vacuum Distillation

The initial step in producing heavy slack wax is vacuum distillation, a process that separates crude oil into different fractions based on their boiling points.

- Crude Oil Heating: Crude oil is heated to a high temperature in a distillation column. Under atmospheric pressure, this would cause thermal cracking, but vacuum distillation allows separation at lower temperatures.

- Fractional Distillation: The heated crude oil is introduced into a vacuum distillation tower, where it separates into various fractions. The heavier fractions, including waxy distillates, are collected at the bottom.

2. Solvent Dewaxing

Solvent dewaxing is the key process for extracting wax from the heavy distillate fractions obtained from vacuum distillation.

- Mixing with Solvents: The waxy distillates are mixed with solvents such as methyl ethyl ketone (MEK) or toluene, which dissolve the oil and separate it from the wax.

- Cooling: The mixture is cooled to very low temperatures, causing the wax to crystallize and precipitate out of the solution.

- Filtration: The solidified wax is separated from the solvent-oil mixture using filtration. The filtrate (oil and solvent) is collected separately.

3. Filtration and Separation

Filtration and Separation – After the solvent dewaxing process, the wax is further processed to achieve the desired oil content and purity.

- Filtering: The slack wax is filtered to remove any remaining solvent and oil impurities.

- Centrifugation: In some cases, centrifugation is used to further purify the wax by spinning it at high speeds to separate out any remaining oil.

- Final Refining: The wax undergoes final refining steps, such as bleaching and deodorizing, to improve its color and odor.

Uses and Applications of Heavy Slack Wax (2-5% Oil Content)

Heavy slack wax with 2-5% oil content is used across a wide range of industries due to its unique properties. Here are some of its most common uses and applications:

1. Candle Manufacturing

Slack wax is widely used in the candle industry as a primary ingredient for making various types of candles.

Applications in Candle Manufacturing

- Container Candles: Heavy slack wax is often used to make container candles. Its medium melting point and oil content provide good burn characteristics and fragrance retention.

- Pillar Candles: It is also used for making pillar candles, where its hardness and structural integrity help maintain the candle’s shape during burning.

- Blending: Slack wax can be blended with other waxes, such as paraffin wax or stearic acid, to achieve specific melting points and performance characteristics.

2. Rubber Industry

In the rubber industry, slack wax serves as a processing aid and lubricant.

Applications in the Rubber Industry

- Processing Aid: Slack wax is used to improve the processing and extrusion of rubber compounds. It reduces viscosity and enhances the flow properties of rubber during molding and extrusion processes.

- Internal Lubricant: It acts as an internal lubricant, reducing friction and wear during the mixing and molding of rubber, which extends the life of processing equipment.

- Anti-Tack Agent: Slack wax is applied to rubber sheets to prevent them from sticking together, facilitating easier handling and storage.

3. Coatings and Emulsions

Heavy slack wax is an essential ingredient in various coatings and emulsions used in industrial applications.

Applications in Coatings and Emulsions

- Wood Coatings: It is used in wood coatings to provide a protective layer that enhances the durability and appearance of wood products. The wax offers water repellency and a smooth finish.

- Paper Coatings: Slack wax is used in paper coatings to impart water resistance and improve the texture and printability of paper products.

- Emulsions: It is used to produce wax emulsions that serve as coating agents for textiles, leather, and other materials. These emulsions provide flexibility, water resistance, and improved handling characteristics.

4. Textile Industry

Slack wax finds applications in the textile industry for fabric finishing and processing.

Applications in the Textile Industry

- Softening Agent: It is used as a softening agent to improve the hand feel and drape of fabrics, making them more comfortable to wear.

- Water Repellency: Slack wax is applied to textiles to impart water-repellent properties, making them suitable for outdoor and weather-resistant applications.

- Finishing Agent: It is used in fabric finishing processes to enhance the appearance, durability, and performance of textiles.

5. Adhesives and Sealants

Heavy slack wax is used in the production of adhesives and sealants to enhance their performance and application properties.

Applications in Adhesives and Sealants

- Hot Melt Adhesives: Slack wax improves the viscosity and thermal stability of hot melt adhesives, ensuring smooth application and strong bonding.

- Sealants: It provides flexibility, durability, and resistance to environmental factors in sealants, ensuring long-lasting sealing performance.

6. Industrial Lubricants

Slack wax is used as a base material in the formulation of industrial lubricants.

Applications in Industrial Lubricants

- Lubricating Greases: It is used in the production of lubricating greases, providing a consistent texture and improving the grease’s performance under high temperatures and pressures.

- Metalworking Fluids: Slack wax is used in metalworking fluids to reduce friction and wear during machining and forming processes, extending tool life and improving surface finishes.

- Mold Release Agents: It is used as a mold release agent in various manufacturing processes, preventing products from sticking to molds and facilitating easy removal.

7. Personal Care Products

In the personal care industry, slack wax is used in various formulations to enhance product performance.

Applications in Personal Care Products

- Lotions and Creams: Slack wax is used in lotions and creams to provide a smooth, silky texture and improve the product’s stability and spreadability.

- Lip Balms and Lipsticks: It is used in lip balms and lipsticks to provide structure and enhance the product’s moisture-retaining properties.

- Hair Care Products: Slack wax is used in hair care products, such as pomades and styling waxes, to provide hold and shine while conditioning the hair.

Benefits of Using Heavy Slack Wax (2-5% Oil Content)

Heavy slack wax offers numerous benefits across various industries due to its unique properties and versatility. Here are some of the key benefits of using heavy slack wax:

1. Cost-Effectiveness

Heavy slack wax is a cost-effective material compared to other types of waxes. Its lower production costs and versatile applications make it an economical choice for various industries.

2. Enhanced Product Performance

Slack wax enhances the performance of end products by providing properties such as water repellency, flexibility, and improved texture. This results in high-quality products that meet industry standards and consumer expectations.

3. Versatility

Heavy slack wax is a highly versatile material that can be used in a wide range of applications across various industries. Its ability to enhance different properties makes it a valuable additive in candles, coatings, adhesives, textiles, and more.

4. Improved Processing Efficiency

Slack wax improves the processing efficiency of various materials by reducing friction, improving flow properties, and preventing sticking. This leads to smoother manufacturing processes and reduced wear on machinery.

5. Environmental Benefits

Using slack wax can lead to environmental benefits by reducing the need for synthetic additives and chemicals. Its use in coatings, adhesives, and lubricants can also reduce the environmental impact of these products by providing natural water repellency and reducing the release of harmful substances.

Peak Universal Business: Your Trusted Supplier of Heavy Slack Wax (2-5% Oil Content)

Peak Universal Business is a leading supplier of high-quality heavy slack wax with 2-5% oil content. With a commitment to excellence and customer satisfaction, they offer a wide range of slack wax products tailored to meet the specific needs of their clients.

Why Choose Peak Universal Business?

- Quality Assurance: Peak Universal Business ensures the highest quality standards in their slack wax products, guaranteeing consistency and reliability.

- Technical Expertise: Their team of experts provides technical support and guidance, helping customers optimize the use of slack wax in their applications.

- Customized Solutions: They offer customized slack wax solutions to meet the unique requirements of different industries and applications.

- Sustainability Focus: Peak Universal Business is committed to sustainability and environmentally responsible practices in the production and supply of slack wax.

Conclusion

Heavy slack wax (2-5% oil content) is a versatile and valuable material with a wide range of uses and applications across various industries. Its unique properties, such as medium melting point, flexibility, and water repellency, make it suitable for enhancing the performance of candles, coatings, adhesives, rubber, textiles, and more. The manufacturing process of slack wax involves several steps, including vacuum distillation, solvent dewaxing, and filtration, to achieve the desired oil content and purity.

Peak Universal Business stands out as a reliable supplier of high-quality slack wax, offering technical expertise, customized solutions, and a commitment to sustainability. By understanding the properties, production process, and diverse applications of heavy slack wax, manufacturers can make informed decisions to enhance their products and processes, ultimately achieving greater success in their industries. (Production Methods: Vacuum Distillation, Solvent Dewaxing, Filtration and Separation)

You can Read More about this product Here:

Properties and Uses of Heavy Slack Wax 8-12%

What is the Application of Slack Wax?

How Heavy Slack Wax 5 to 8% Oil Content is Manufactured

Slack Wax & Its Applications in Rubber Industry

If You have any other Query or Question you want to ask, Please don’t hesitate to Contact Us

- 0 comment

Leave a Reply