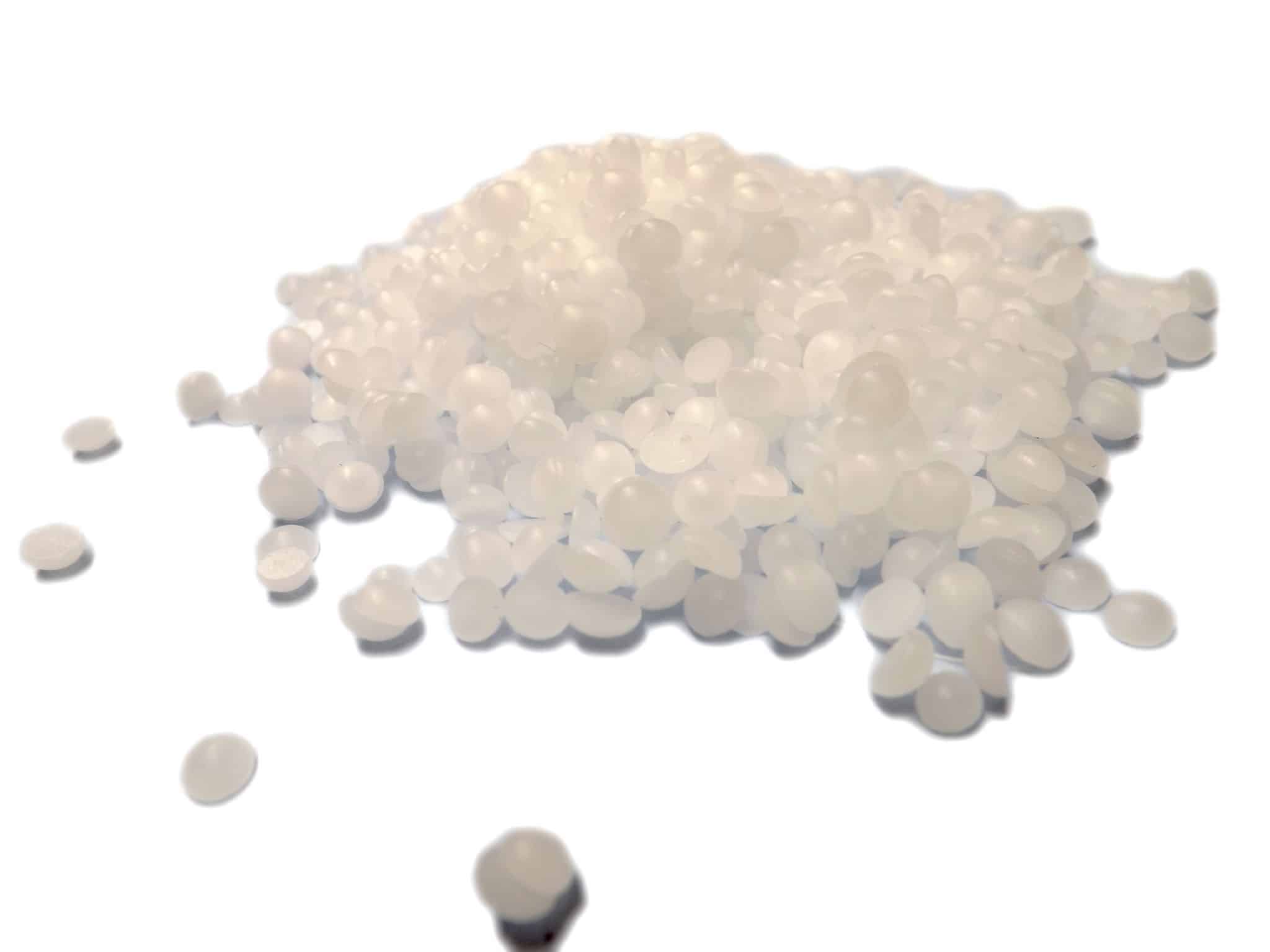

Product Overview

Microcrystalline Wax is a specialized type of wax produced through the de-oiling of petrolatum during the petroleum refining process.

Unlike paraffin wax, which primarily consists of unbranched alkanes, microcrystalline wax contains a higher proportion of iso-paraffinic (branched) hydrocarbons and naphthenic hydrocarbons.

This wax is characterized by its fine crystals, in contrast to the larger crystals found in paraffin wax. It is composed of high molecular weight saturated aliphatic hydrocarbons. Microcrystalline wax is typically darker, more viscous, denser, tackier, and more elastic than paraffin waxes, with a higher molecular weight and melting point.

In summary, microcrystalline wax is a specialized wax with unique properties, making it suitable for various applications in industries such as cosmetics, pharmaceuticals, and food packaging.

Microcrystalline waxes are renowned for their elastic and adhesive properties, which stem from their non-straight chain components. These waxes boast a unique crystal structure that is small and thin, rendering them more flexible than paraffin wax. They are commonly employed in cosmetic formulations due to their desirable characteristics.

When produced by wax refiners, microcrystalline waxes are typically manufactured to meet various ASTM specifications, including congeal point (ASTM D938), needle penetration (D1321), color (ASTM D6045), and viscosity (ASTM D445).

Microcrystalline wax can be broadly categorized into “laminating” grades and “hardening” grades. Laminating grades typically have a melting point of 140-175°F (60-80°C) and a needle penetration of 25°C or above. On the other hand, hardening grades range from about 80-93°C, with a needle penetration of 25°C or below. The color of both grades can vary from brown to white, depending on the degree of processing at the refinery level.

Microcrystalline waxes are derived from the refining of heavy distillates from lubricant oil production. This byproduct is then de-oiled at a wax refinery. Depending on the intended use and desired specifications, the product may undergo further processing to remove Odor and color, which typically starts as brown or dark yellow. This is typically achieved through filtration methods or by hydro-treating the wax material.

Packaging

At Peak Universal Business, Microcrystalline wax is available in 5 Kg slabs which are then packed in Cartons or gunny, and We also provide custom packaging option for this product as well.

Microcrystalline Wax Technical Data Sheet:

The Peak Universal Business team is dedicated to providing you with the most suitable products for your projects, ensuring quality and reliability.

For more detailed explanations about our Microcrystalline Wax and its technical specifications, please don’t hesitate to contact Peak Universal Business. We are here to assist you.